Multi-Spindle Customization in Multi-Axis Systems for Industrial Automation

| Product Name | Applicable industries |

| Servo Screwdriver Robot | Security Equipment Manufacturing |

Multi-Spindle Customization in Multi-Axis Systems

In the ever-evolving landscape of industrial automation, the demand for precision, efficiency, and adaptability has never been higher. One of the most significant advancements in this field is the integration of multi-spindle customization within multi-axis systems. This technology is revolutionizing manufacturing processes by enabling simultaneous operations, reducing cycle times, and improving overall productivity.

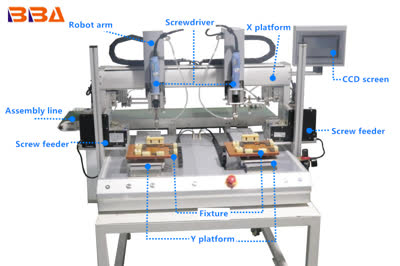

Multi-spindle systems are designed to perform multiple machining operations in a single setup. By incorporating customization options, these systems can be tailored to meet the specific needs of various industries, from automotive to aerospace and beyond. The ability to configure spindle arrangements, tooling, and motion paths ensures that manufacturers can achieve optimal performance for their unique applications.

When combined with multi-axis motion control, multi-spindle systems unlock even greater potential. Multi-axis systems provide the flexibility to move tools and workpieces along multiple planes, enabling complex geometries and intricate designs to be machined with unmatched accuracy. The synergy between multi-spindle customization and multi-axis motion allows for seamless transitions between operations, minimizing idle time and maximizing throughput.

One of the key advantages of multi-spindle customization is its scalability. Whether for high-volume production or specialized low-volume runs, manufacturers can adapt these systems to their requirements without compromising on precision or efficiency. Custom spindle configurations—such as radial, linear, or hybrid arrangements—ensure that each application is addressed with the most effective solution.

Another critical aspect is the integration of smart technologies. Advanced control systems and real-time monitoring capabilities enhance the performance of multi-spindle multi-axis setups. Predictive maintenance, automated tool changes, and adaptive machining strategies further contribute to reducing downtime and extending equipment lifespan.

The future of industrial automation lies in the ability to combine flexibility with precision, and multi-spindle customization in multi-axis systems is at the forefront of this transformation. By leveraging these technologies, manufacturers can stay competitive in an increasingly demanding market, delivering high-quality products with greater efficiency and reliability.

As industries continue to push the boundaries of innovation, the role of customized multi-spindle solutions will only grow. Investing in these systems today paves the way for smarter, faster, and more adaptable manufacturing processes tomorrow.