Entry-Level vs Industrial Robotic Screwdrivers: Key Differences | Automation Tools Guide

As industrial automation continues to evolve, robotic screwdrivers have become essential tools in manufacturing and assembly lines. Whether you're working on small-scale projects or large industrial applications, understanding the differences between entry-level and industrial robotic screwdrivers is crucial for optimizing efficiency and productivity. In this article, we explore the key distinctions between these two categories and help you determine which best suits your needs.

Performance and Precision

Entry-level robotic screwdrivers are designed for lighter-duty tasks, offering sufficient torque and speed for basic assembly operations. These tools are ideal for low-volume production or prototyping, where precision requirements are less stringent. However, industrial robotic screwdrivers are built for high-performance environments. They deliver higher torque consistency, superior accuracy, and repeatability, ensuring reliable fastening even in high-speed production lines.

Durability and Lifespan

Industrial robotic screwdrivers are engineered for longevity. With heavy-duty construction and advanced materials, they withstand harsh conditions such as dust, vibrations, and continuous operation. Entry-level models, while cost-effective, may not endure prolonged heavy use. Frequent maintenance or replacements could offset initial cost savings over time.

Integration and Scalability

Industrial robotic screwdrivers offer advanced integration features, such as PLC compatibility and real-time feedback, making them suitable for fully automated production environments. Entry-level options may lack these capabilities, limiting their use in complex or expanding production setups. Choosing industrial-grade tools ensures scalability as your automation needs grow.

Cost Considerations

While industrial robotic screwdrivers require a higher initial investment, their durability and efficiency reduce long-term operational costs. Entry-level models may seem attractive due to lower upfront expenses, but they may not provide the same return on investment in demanding applications.

Conclusion

Selecting between entry-level and industrial robotic screwdrivers depends on your production volume, precision needs, and long-term automation goals. Investing in industrial-grade equipment ensures reliability, efficiency, and scalability, making it the preferred choice for high-performance manufacturing.

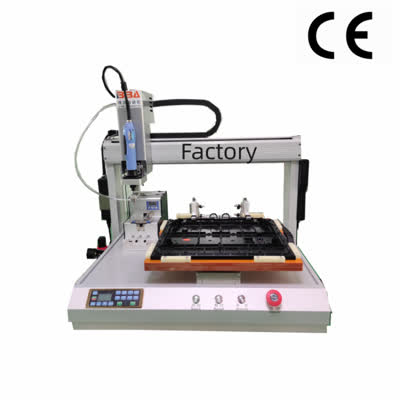

| Product Name | Applicable industries |

| Screw Locking Robot | Industrial Control Panel Assembly |