This semi-automatic PCB soldering machine features a compact, space-saving design, ideal for PCB assembly in limited workspaces. It delivers consistent, precise soldering results, streamlines electronics production workflows, reduces manual effort, and fits seamlessly into small-scale or crowded manufacturing setups.

Semi-automatic soldering machines are automated devices that replace manual soldering operations. They are characterized by their lightweight structure,

stable operation, and convenient maintenance. They are used in industries such as LED soldering and printed circuit board soldering. In the electronics manufacturing

industry, automatic soldering machines are used for soldering mixed circuit boards, thermal components, and sensitive components in the SMT back-end processes.

Coaxial soldering machines employ a PLC + touchscreen design and a high-precision temperature controller, and have a dross-blowing function. No soldering knowledge

is required; even beginners can operate them proficiently.

|

Model

|

BBA-200HX

|

|

power supply

|

AC 110/220V 50/60Hz

|

|

drive mode

|

electric

|

|

power

|

150W

|

|

Temperature range

|

50-550℃

|

|

Temperature accuracy

|

+/-3℃

|

|

Soldering time and solder feeder

|

Adjustable

|

|

welding wire

|

0.6-2.0 mm

|

|

weight

|

15 kg

|

|

External machine dimensions (length * width * height)

|

31*29*32 cm

|

Product Description

Applicable screws

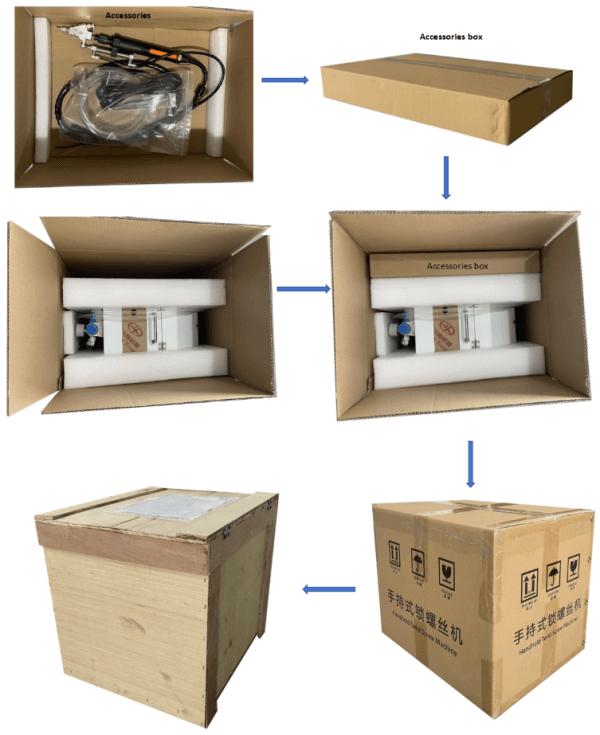

Package