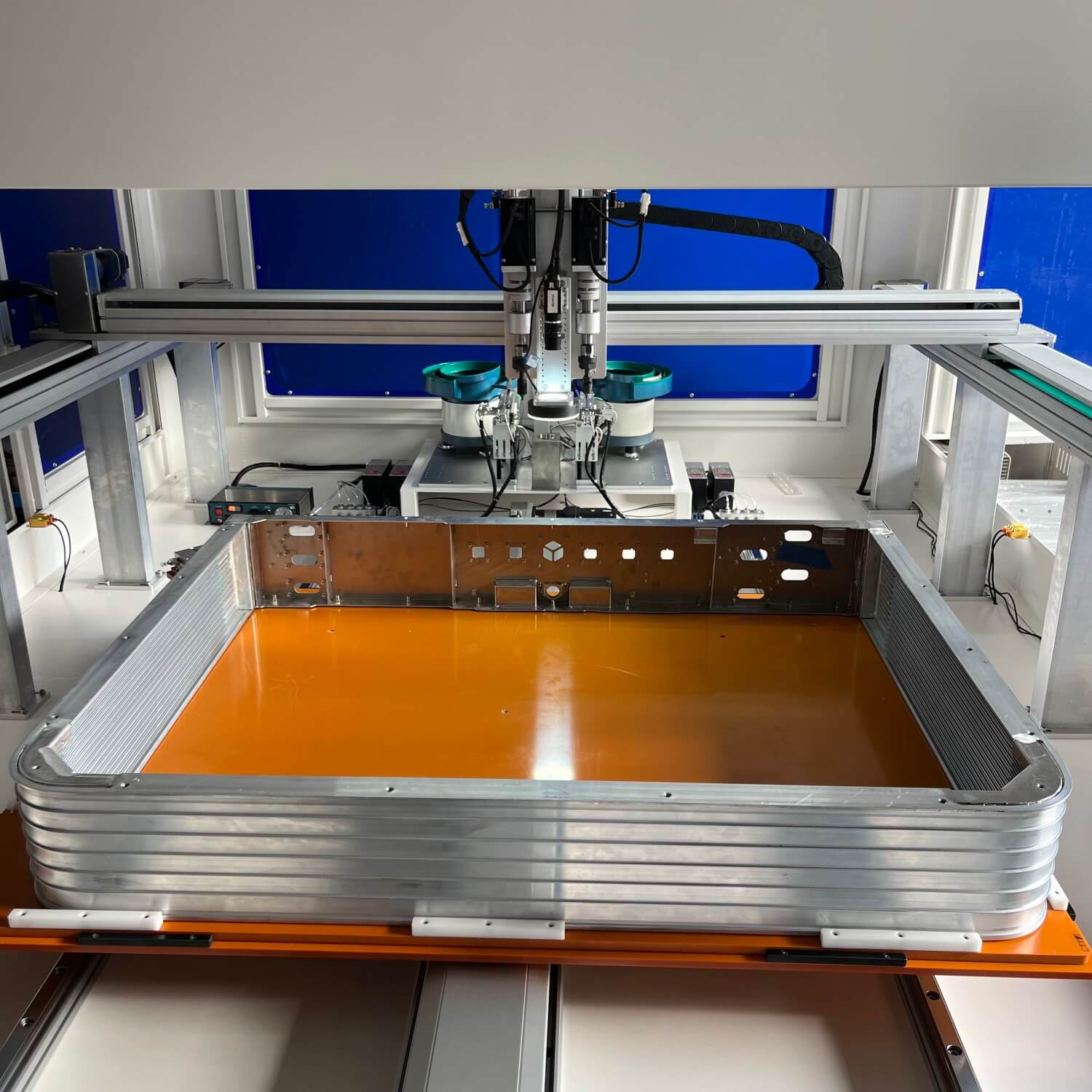

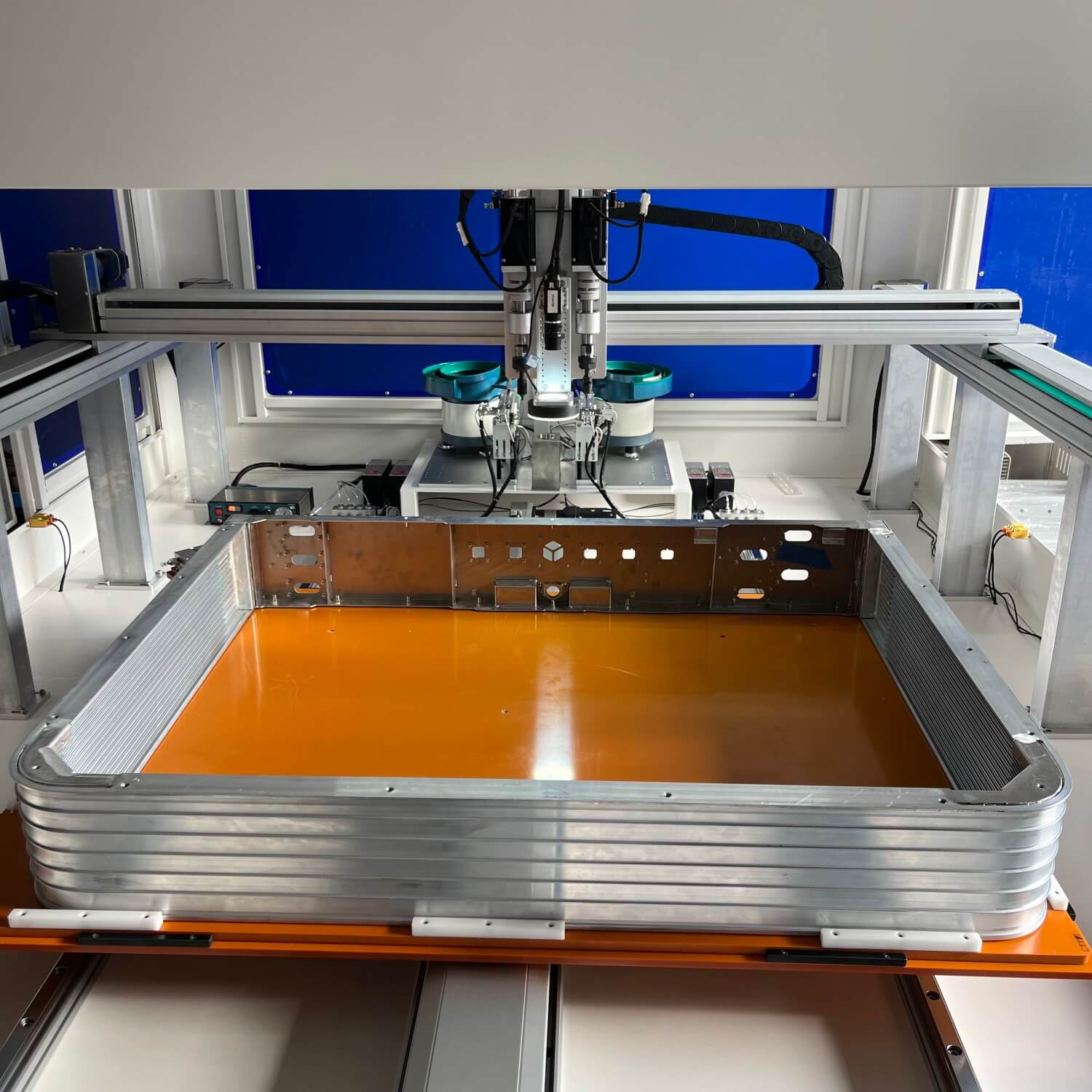

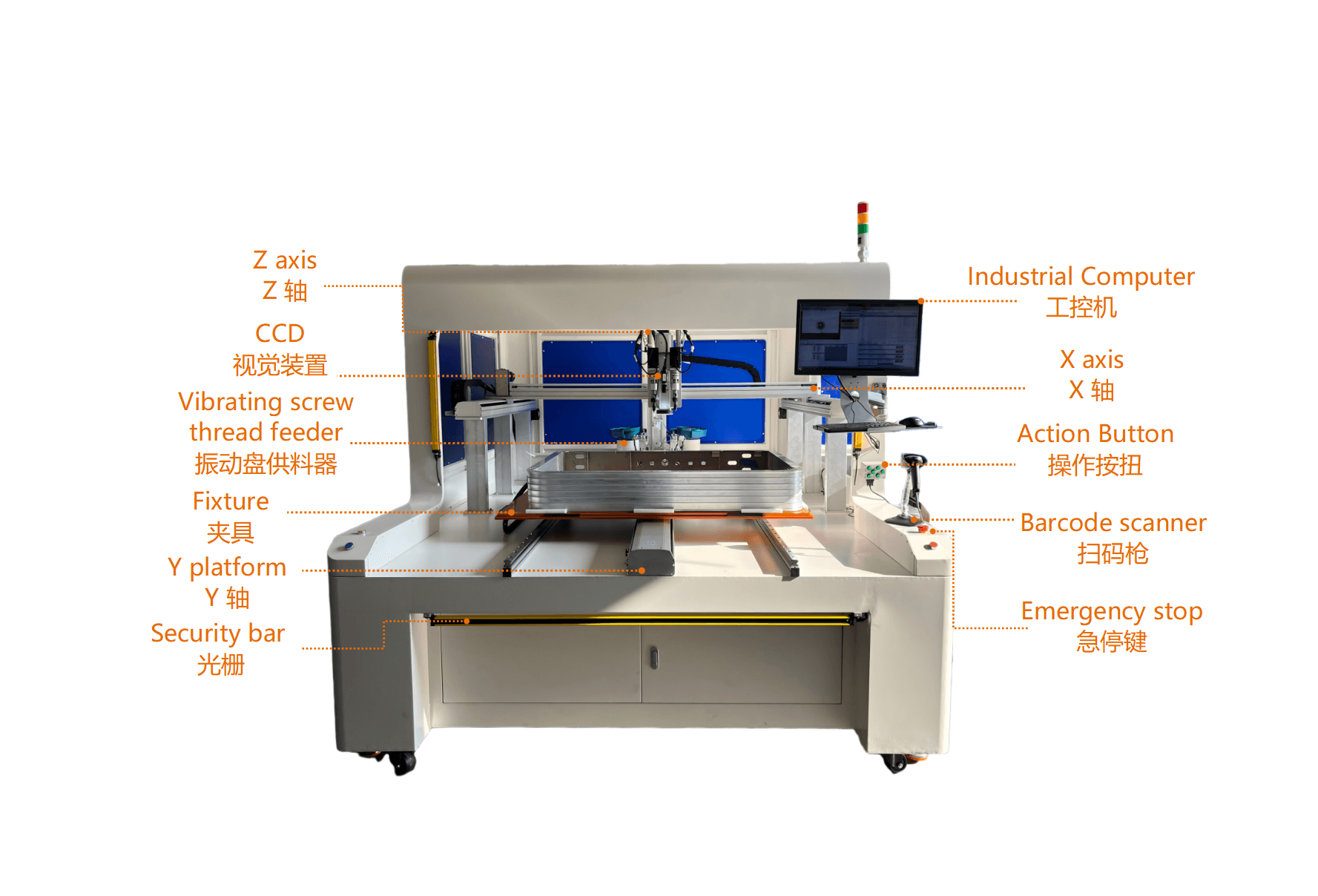

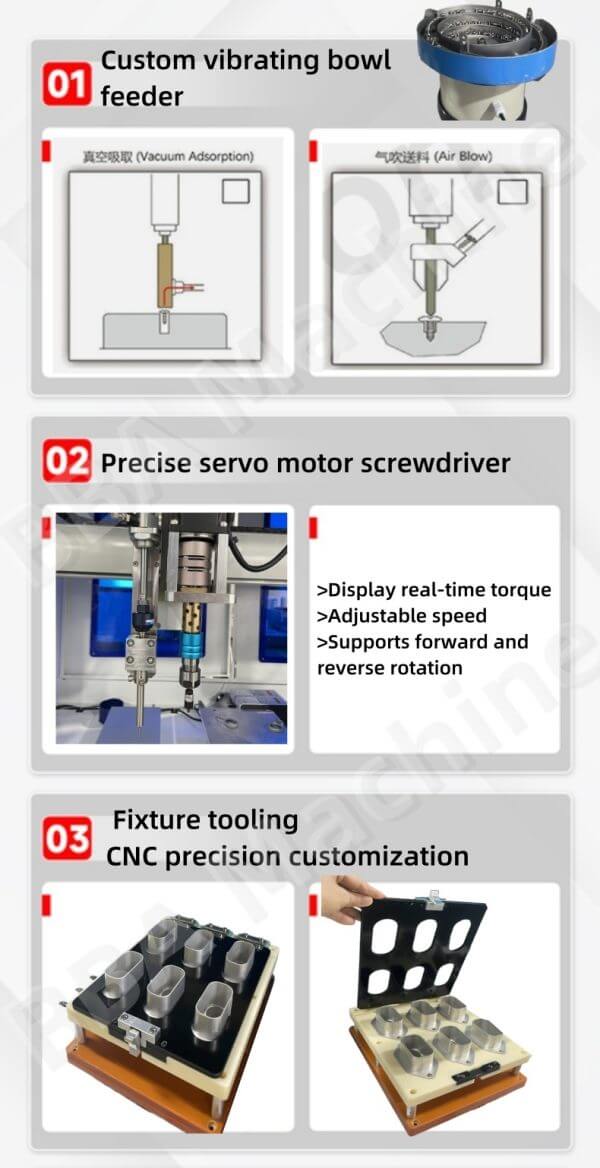

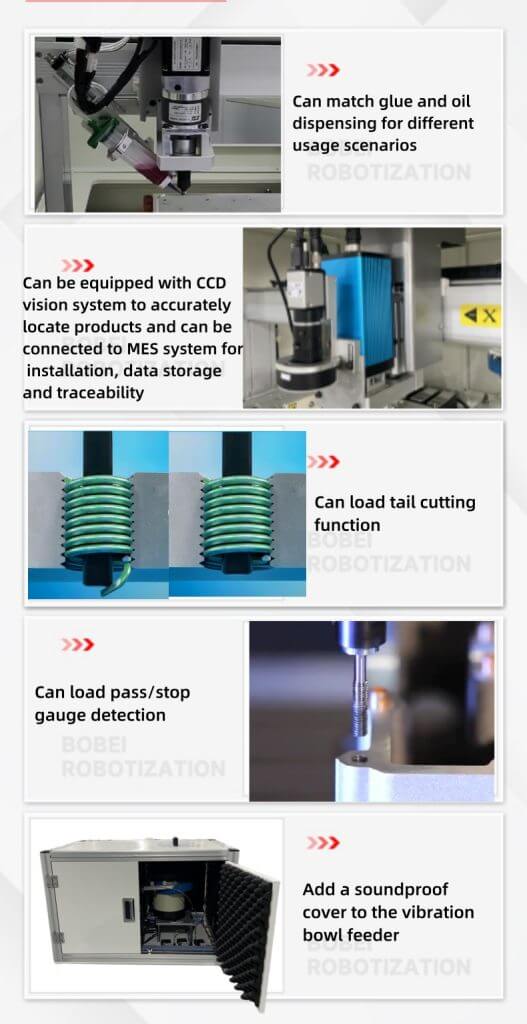

This bench-top automatic threaded insert machine is ideal for compact prototyping and small batch production. It matches the precision of larger automated lines, ensures consistent insert installation, saves workspace, and streamlines low-volume manufacturing workflows efficiently.

| Voltage | AC110/220V 50/60HZ |

| Power | 1000W |

| Stroke | 500*400*400*100mm (X*Y*Z), can be customized |

| Movement speed | 10-500mm/S |

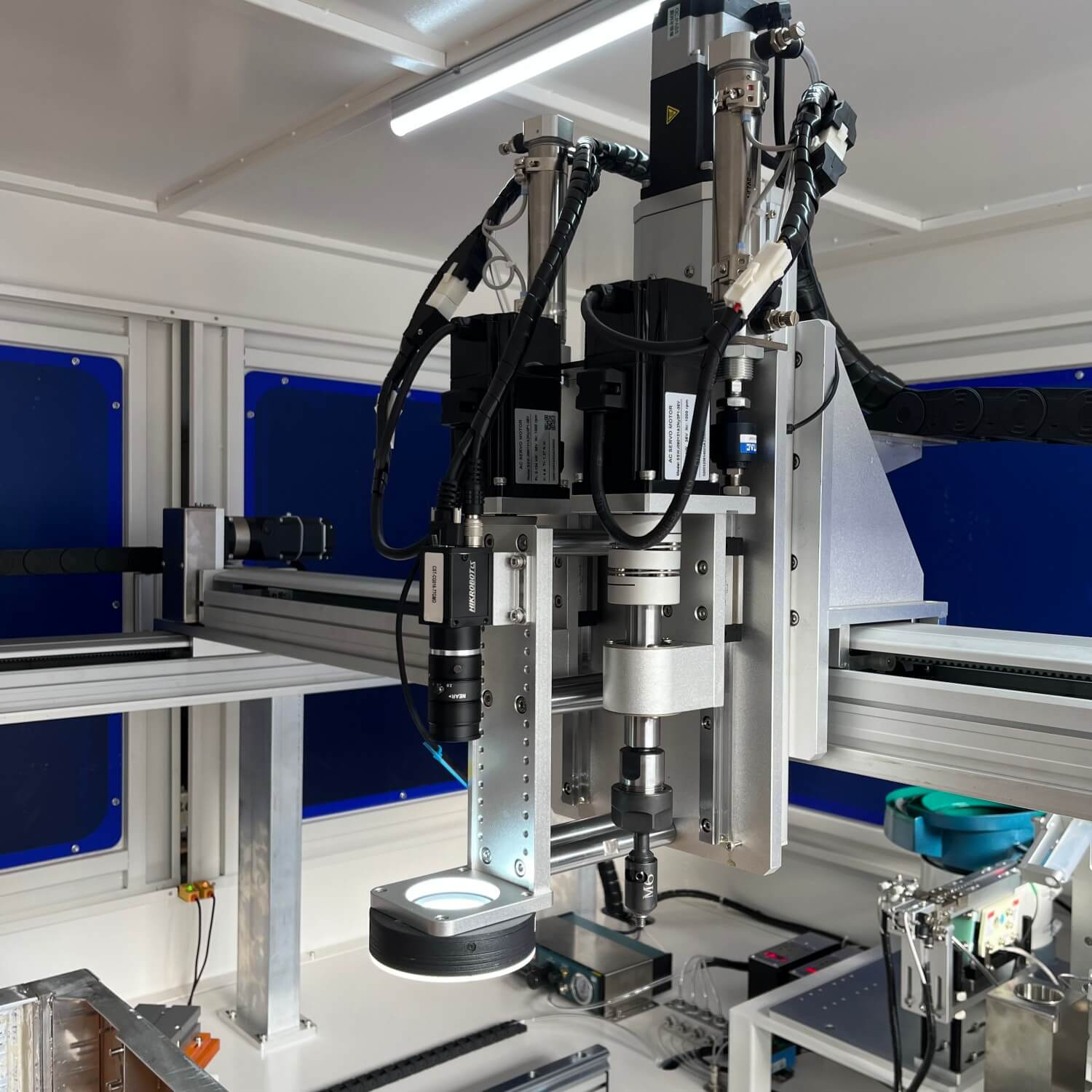

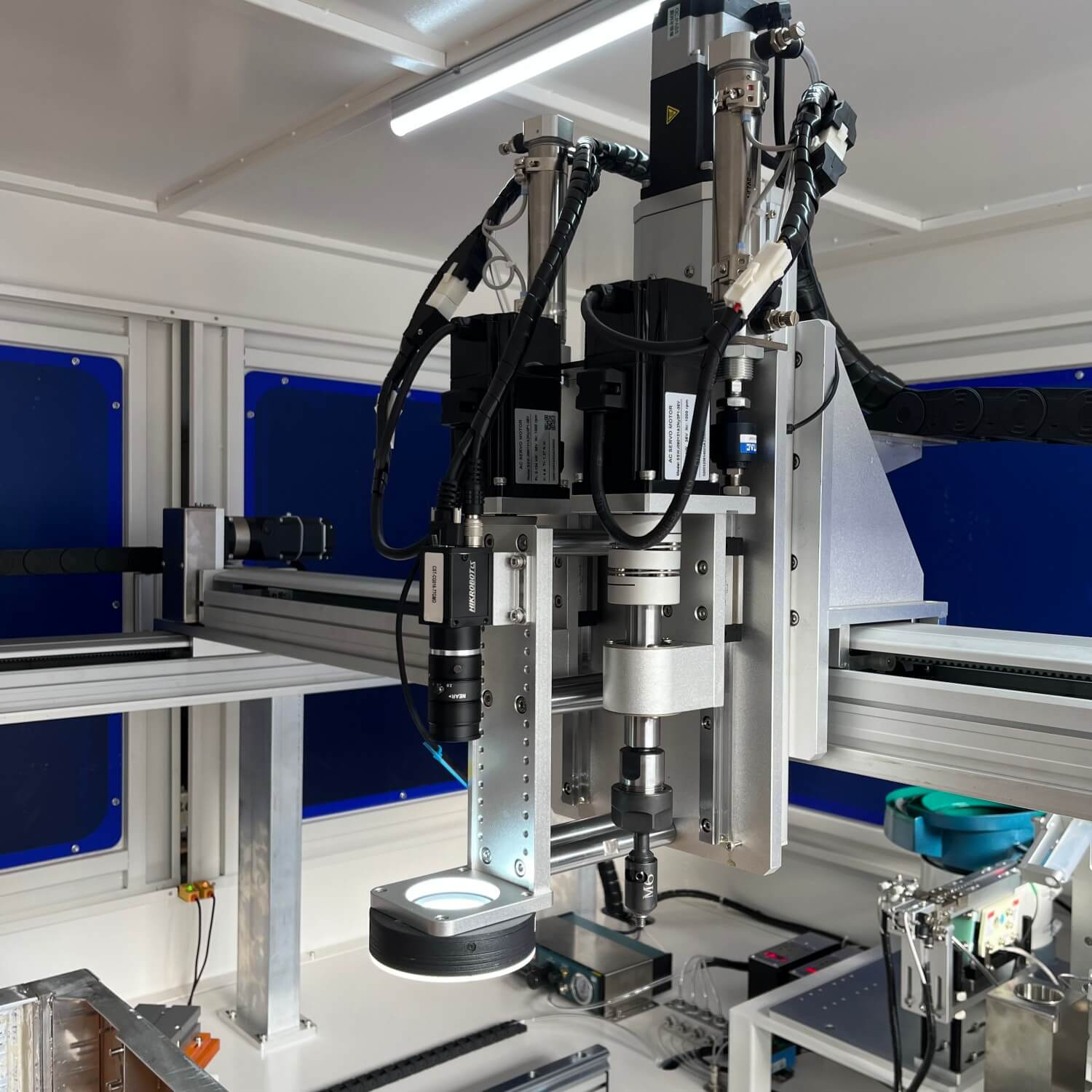

| Position accuracy | ±0.05mm/axis |

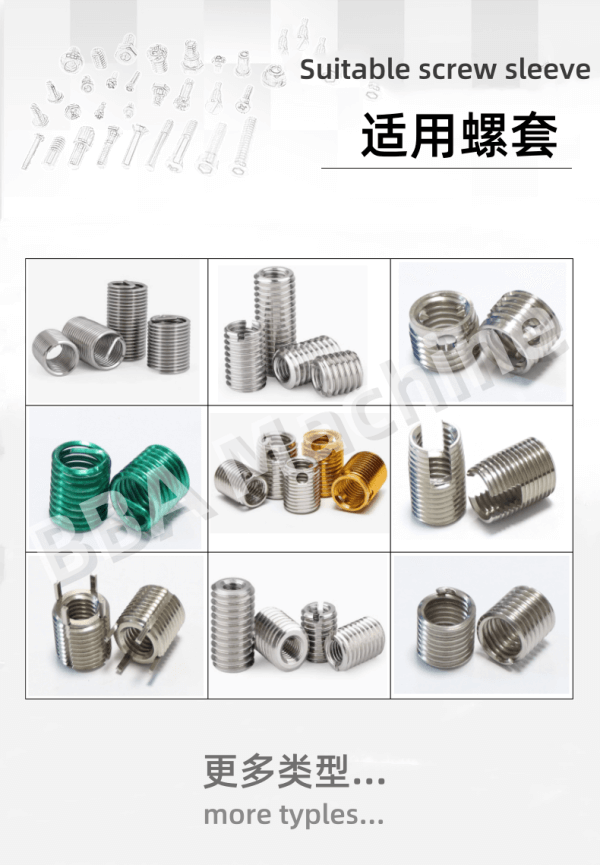

| Universal screw thread | M3-M10 |

| Screw thread height | 6-20mm |

| Screw thread material | Copper, Aluminum, Metal, Stainless steel |

| Screw thread type | Self-tapping thread, screw thread, steel thread |

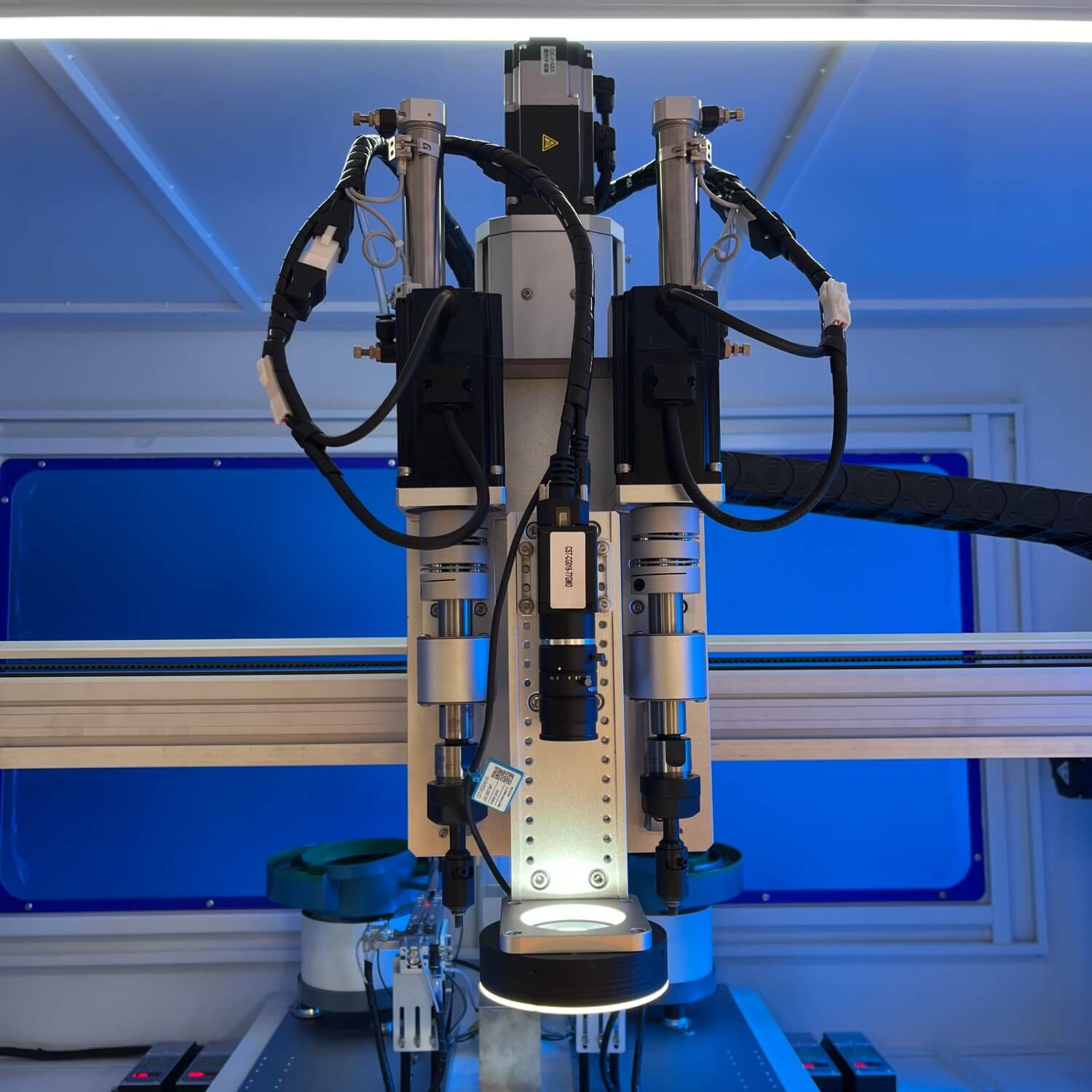

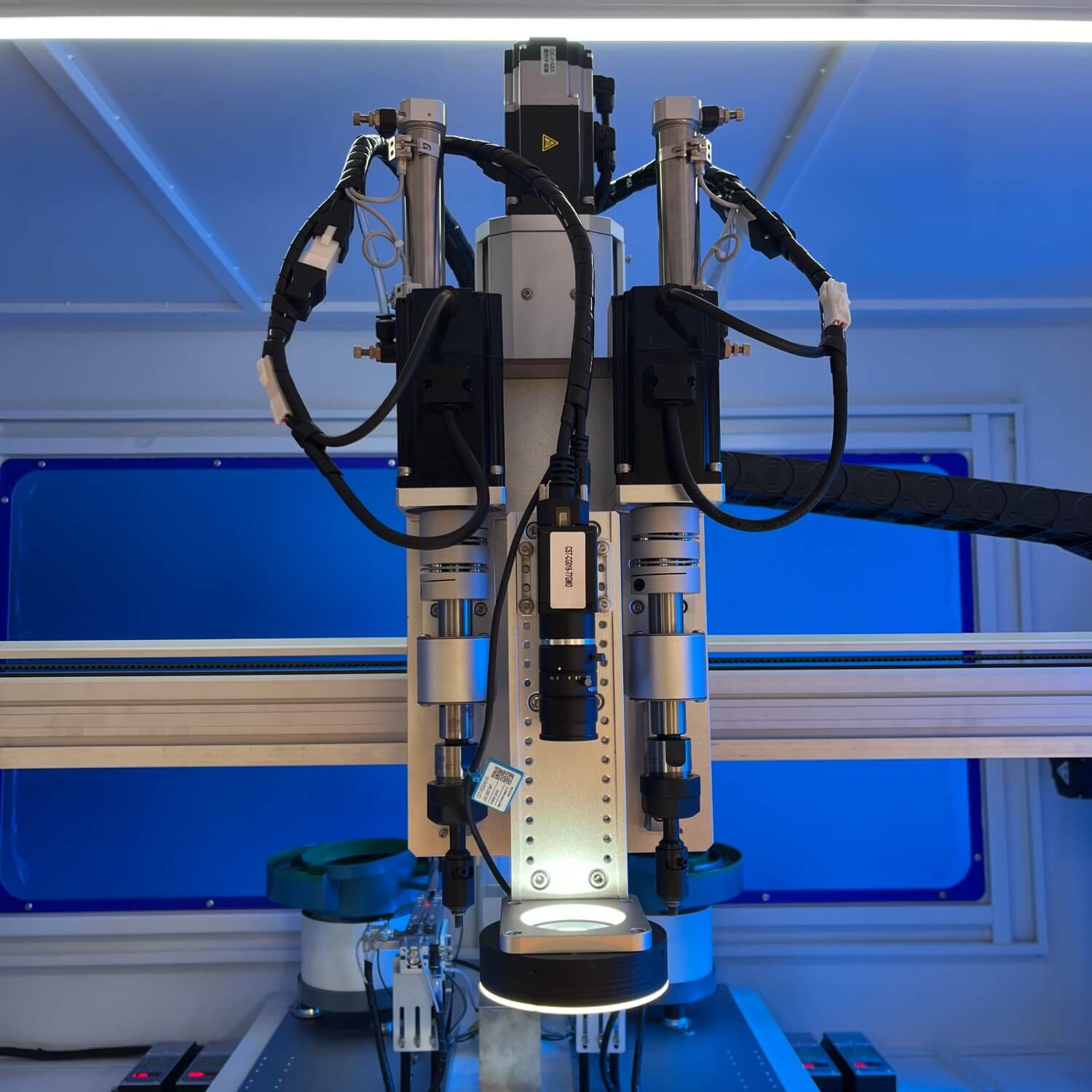

| Transmission mode | Precision toothed belt+guide rail |

| Control panel | PLC+HMI screen |

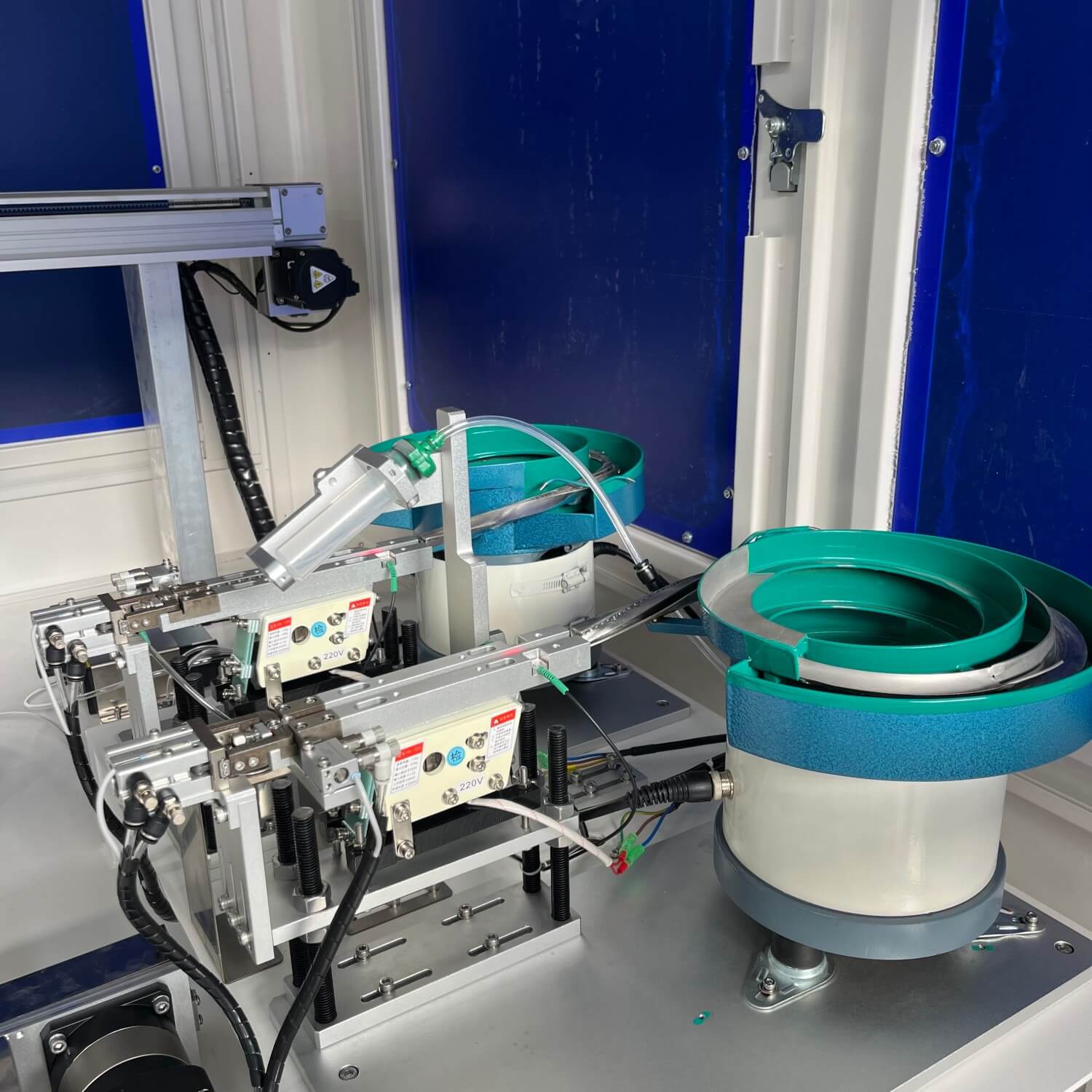

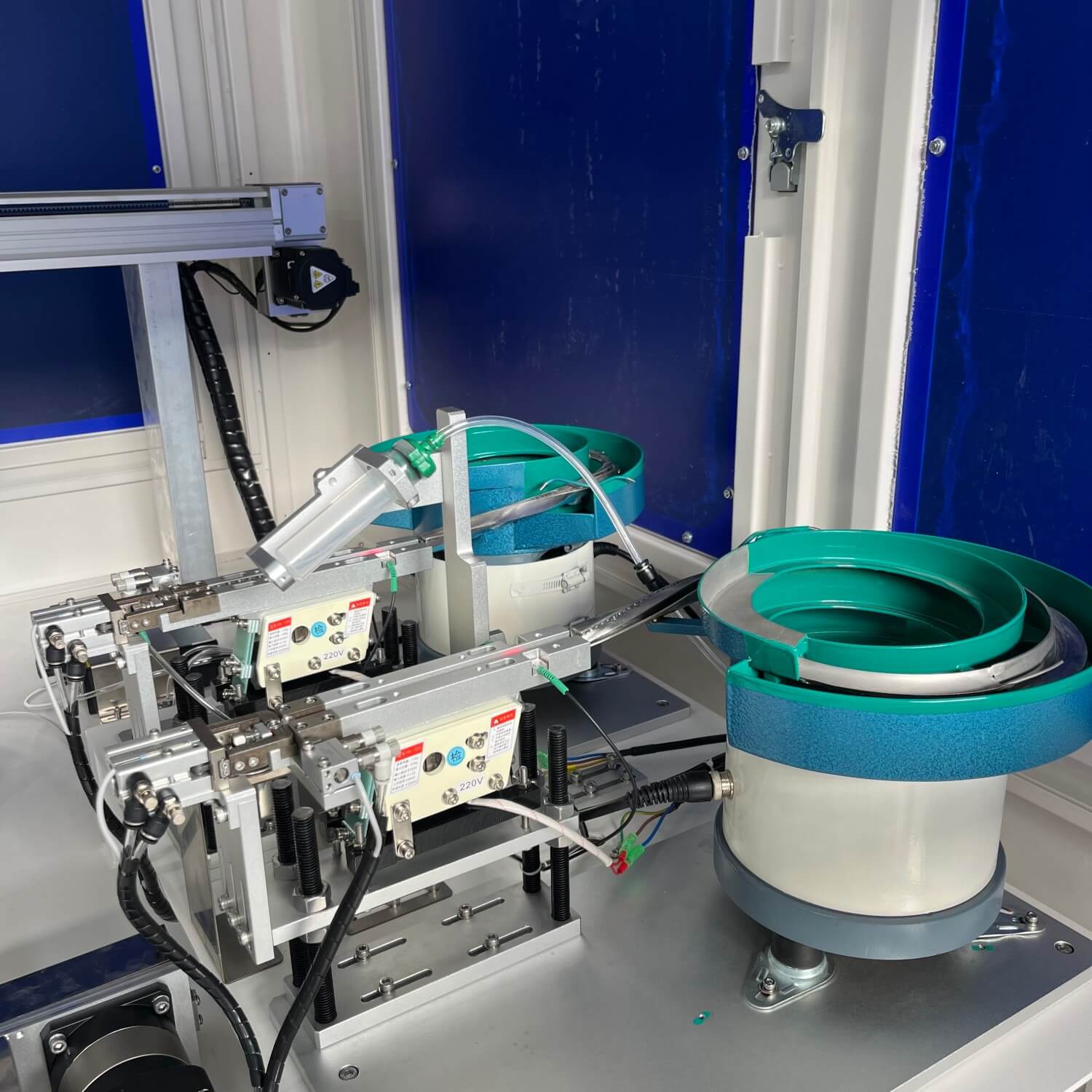

| Conveying mode | Vibrating plate+direct vibrating track |

| Work efficiency | 6S/pcs (include cutting thread tail), details depends on thread size |

| Air pressure | 0.4-0.6Mpa |

| External port | RS232 |

| Program capacity | 12 groups, 20 points per group; can be customized |

| Work environment | Temperature: 5-40℃ Humidity: 20-90% |

| Weight | 580kg(Subject to the actual product) |

| External machine size (L*W*H) | 1150*1350*1650 mm(Can be customized) |

Product Description

Applicable screws

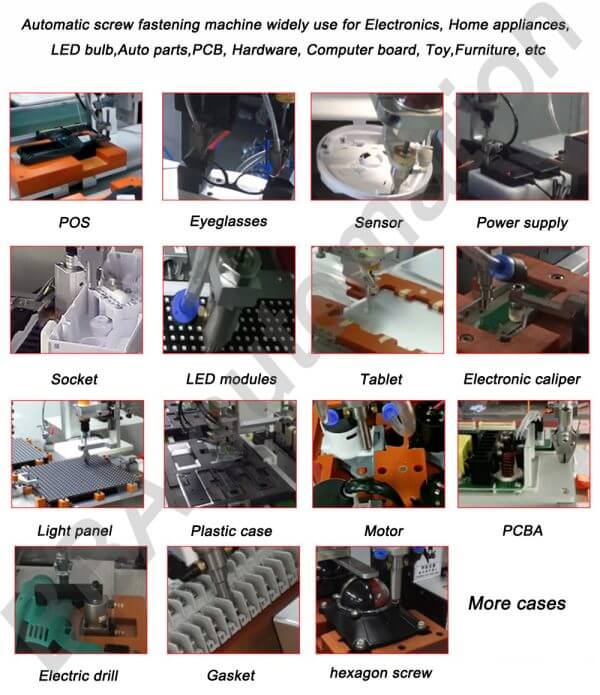

Customer case

Package