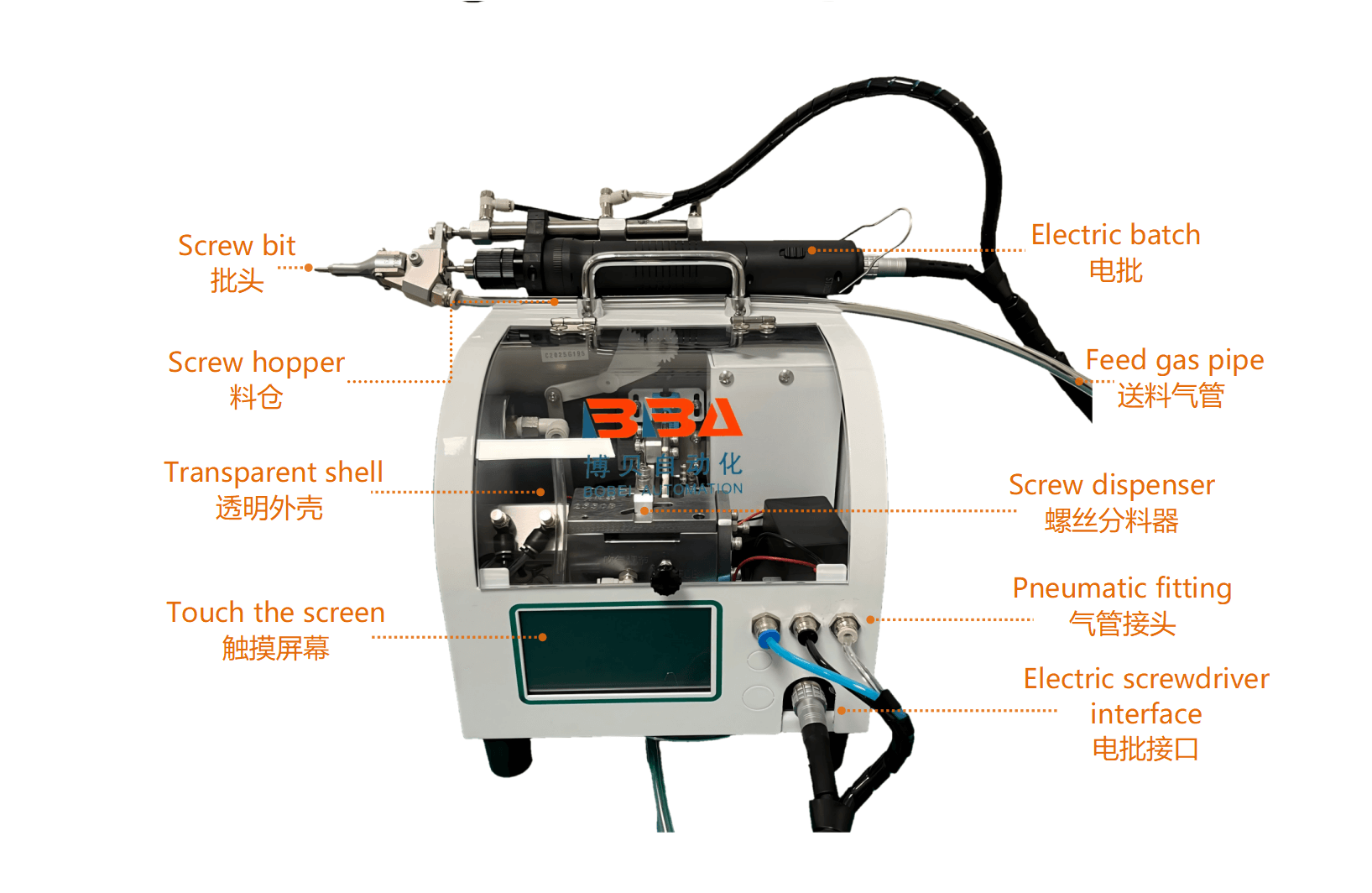

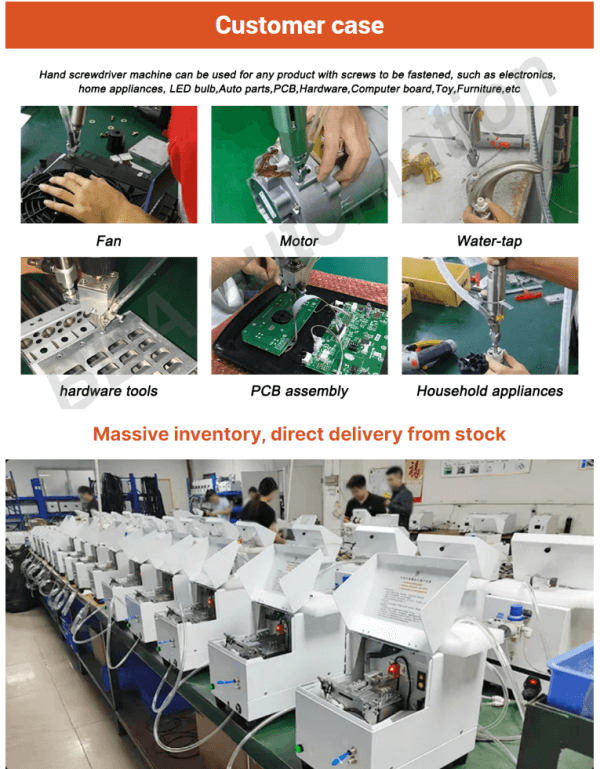

Designed for automotive interior and trim fastening, this semi-automatic screw locking machine has an automatic screw feeder and adjustable torque control. It streamlines assembly, ensures consistent, damage-free fastening, reduces manual effort, and boosts efficiency for automotive interior production lines.

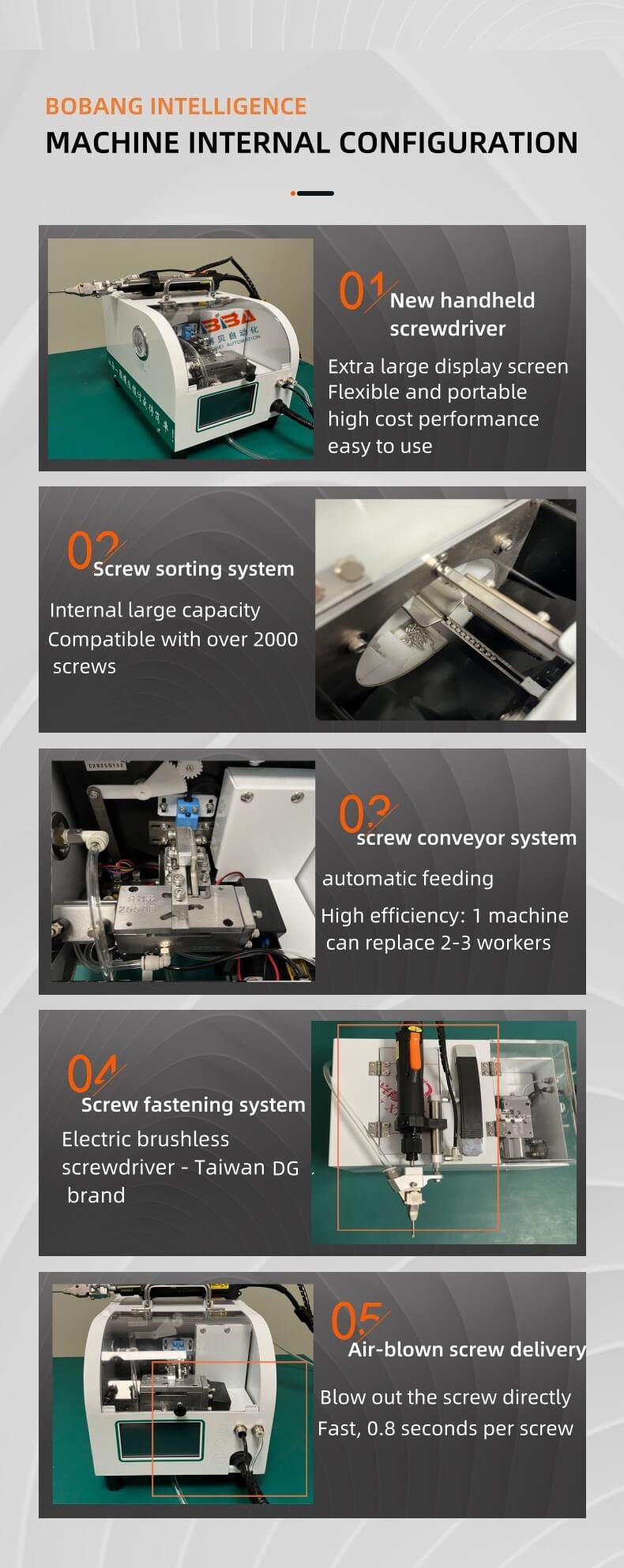

1.One-hand operation, just need a hand to hold the product and align with screw hole for tightening.

2.Fast tightening speed, torsion precision and convenient adjustment for this handheld screwdriver machine with screw feeder.

3.Electric screwdriver in light weight and small size will not hinder the workers’ sight, convenient to store and move.

4.Built-in alert system activates when screws run low

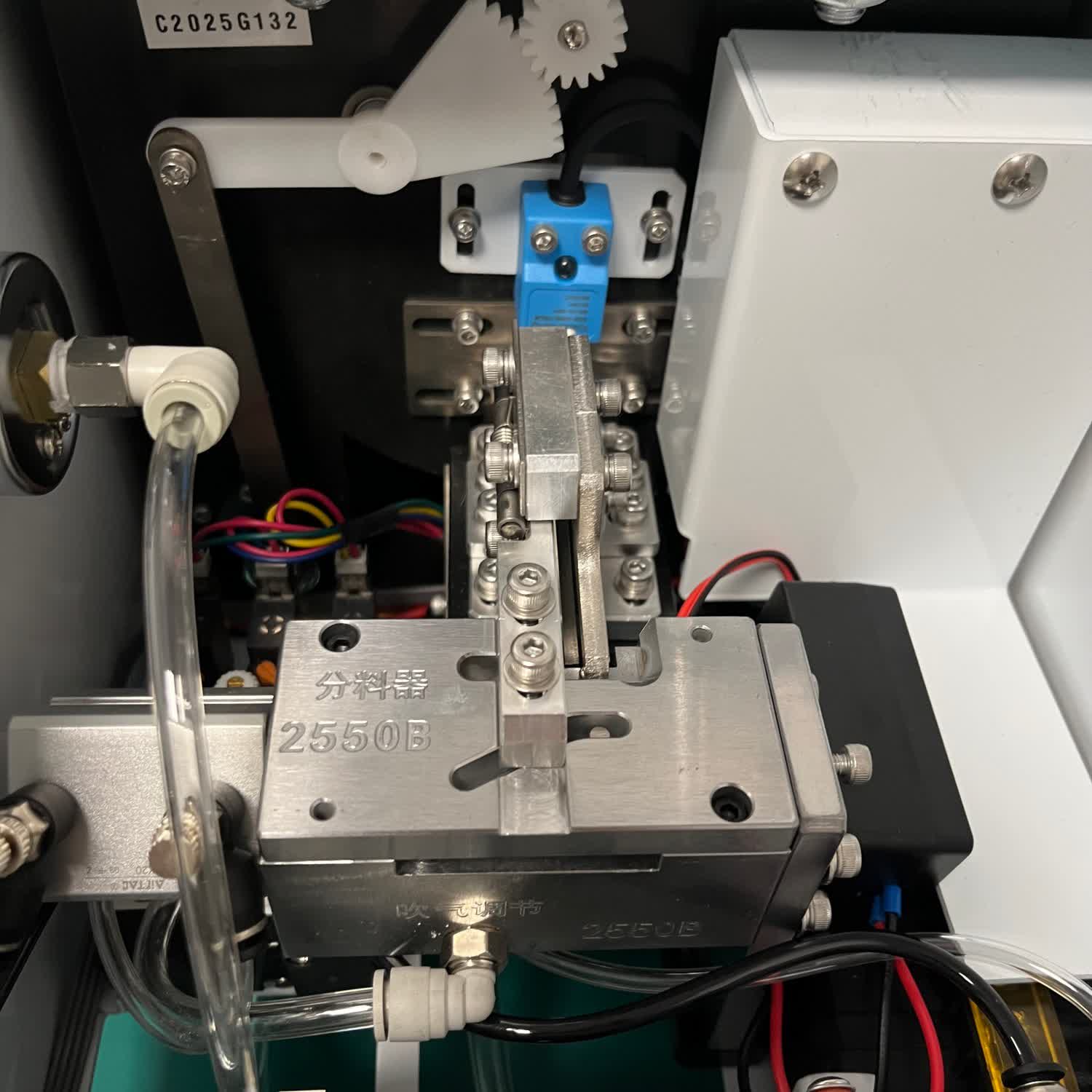

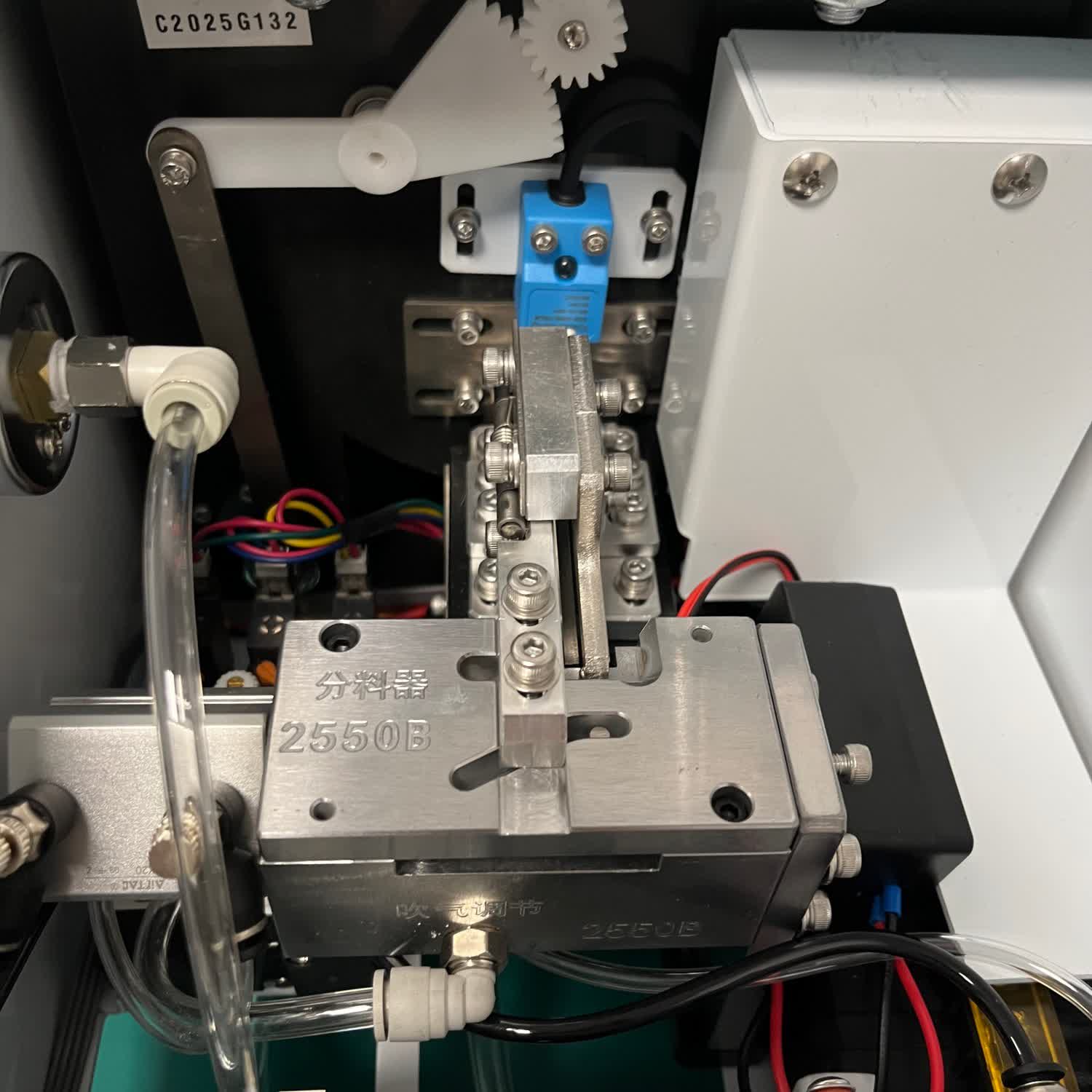

5.Automated screw separation prevents contamination caused by manual handling.

6.Sensor-based mechanism dispenses screws individually, eliminating duplicate feeding.

7.Delivers fast throughput, achieving approximately 50–70 screws per minute.

|

Model |

BBA-100LS |

| Voltage | 110/220V 50/60HZ |

| Feeder capacity | 1000pcs (depends on screw size) |

| Air pressure | 0.5~0.7MPa |

| Conveying distance | 1~3meters |

| Feeder mode | Vibratory feeder |

| Screw delivery method | Auto blowing type feeder |

| Working efficiency | 50~70pcs/minute |

| Applicable screws | M2~M4 |

| Screw head | Tapping screw, pan head, stainless steel etc… |

| Dimension | 35*40*22CM |

| Weight | 20KG |

Product Description

Applicable screws

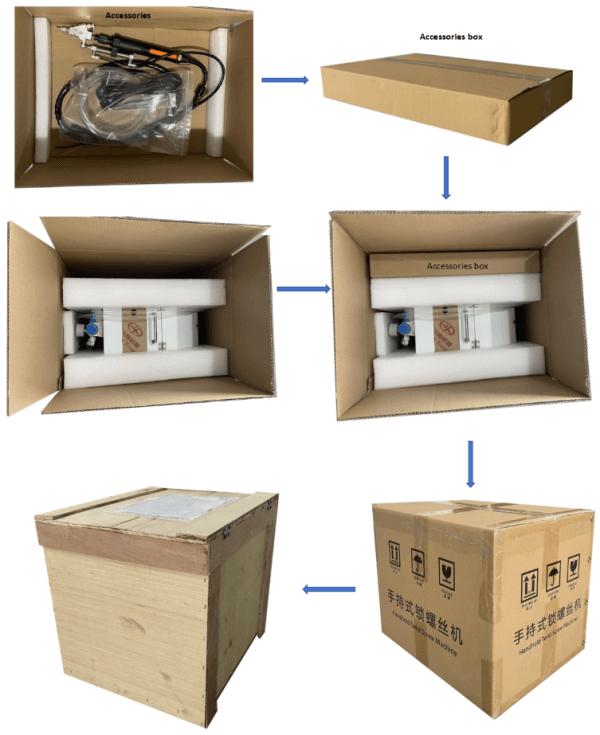

Package