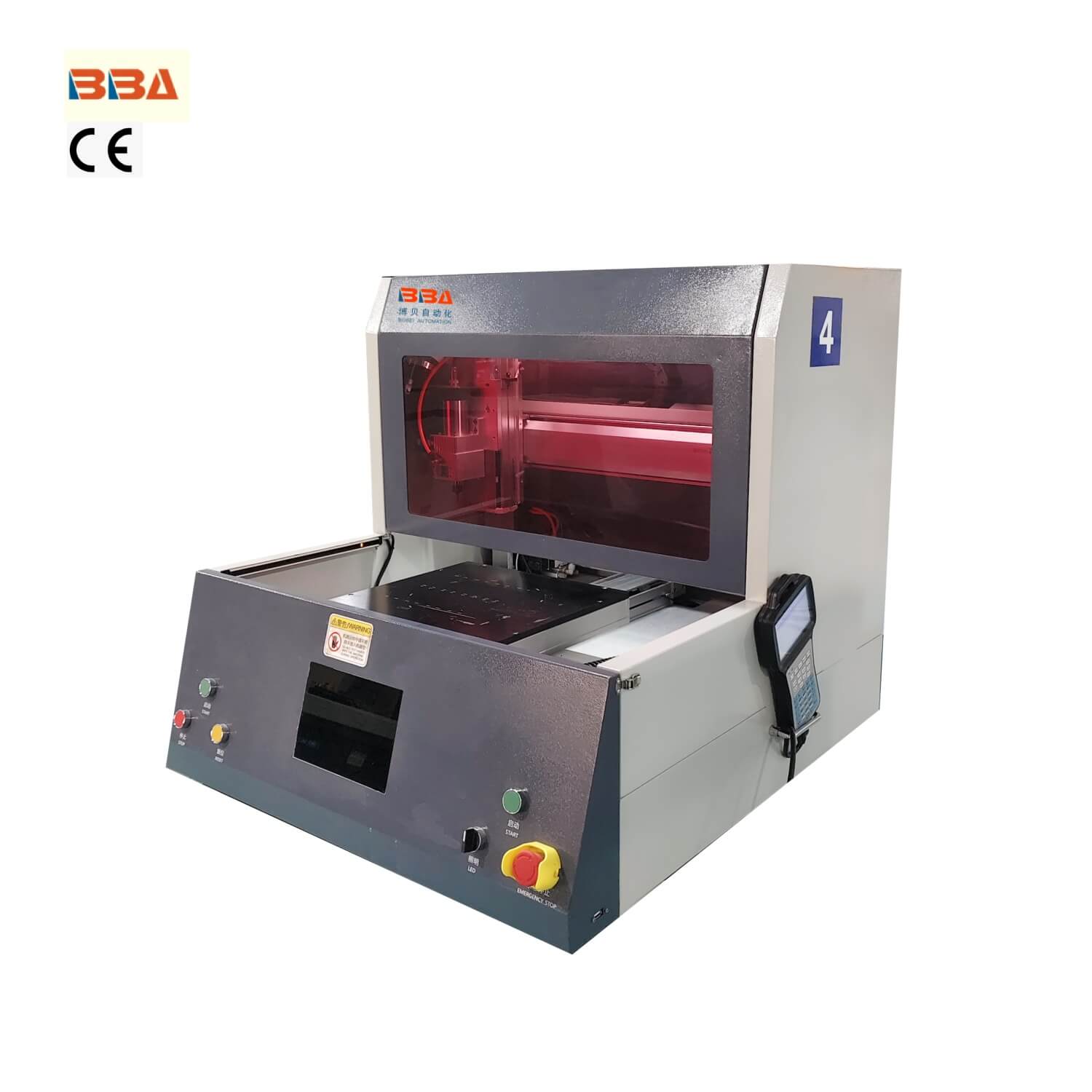

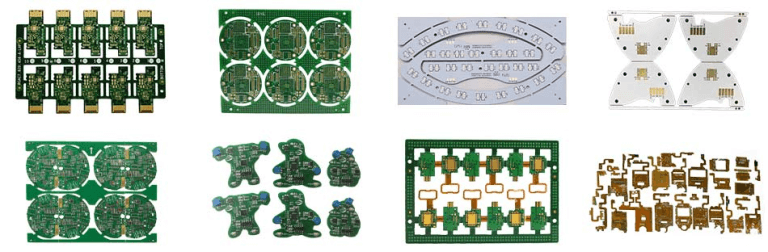

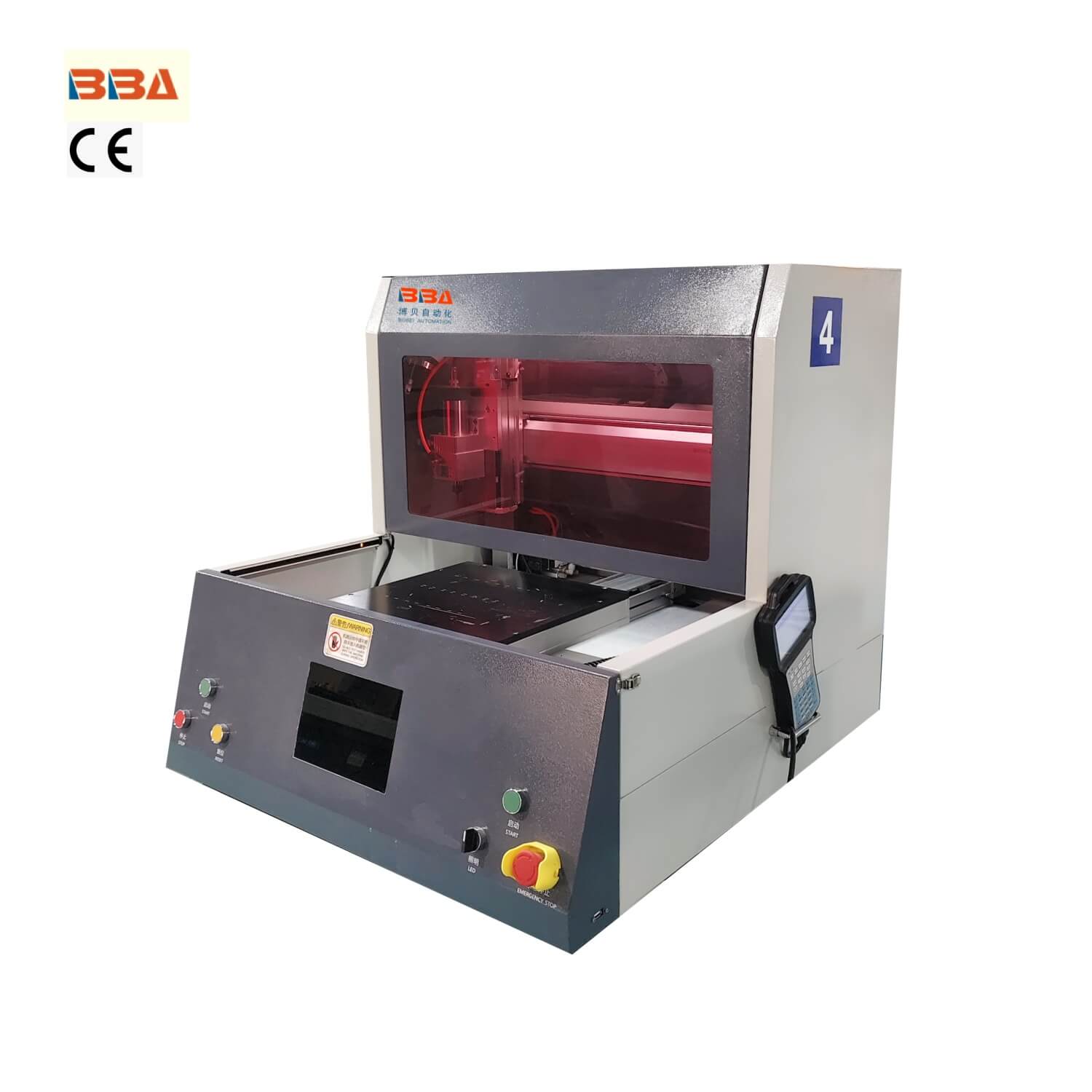

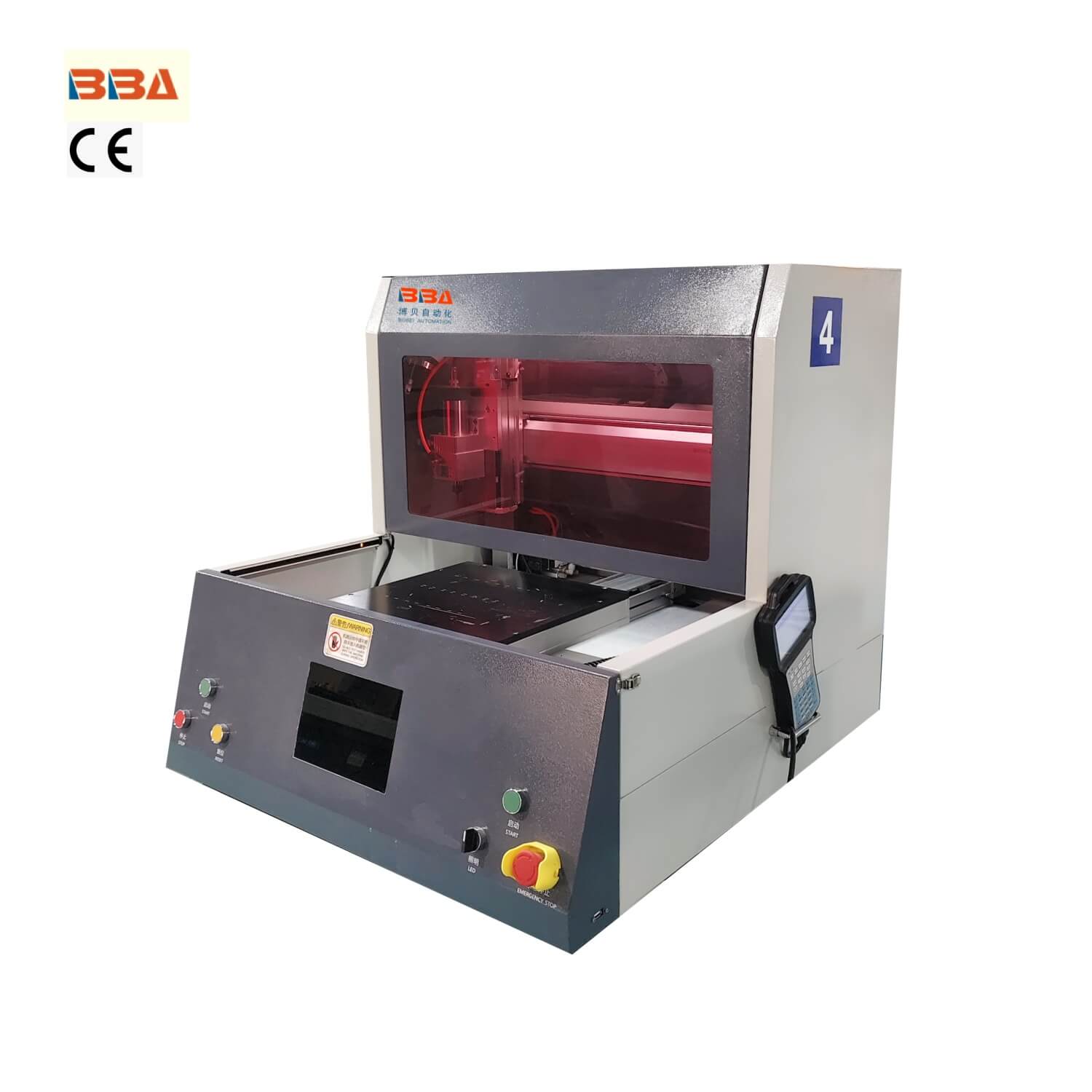

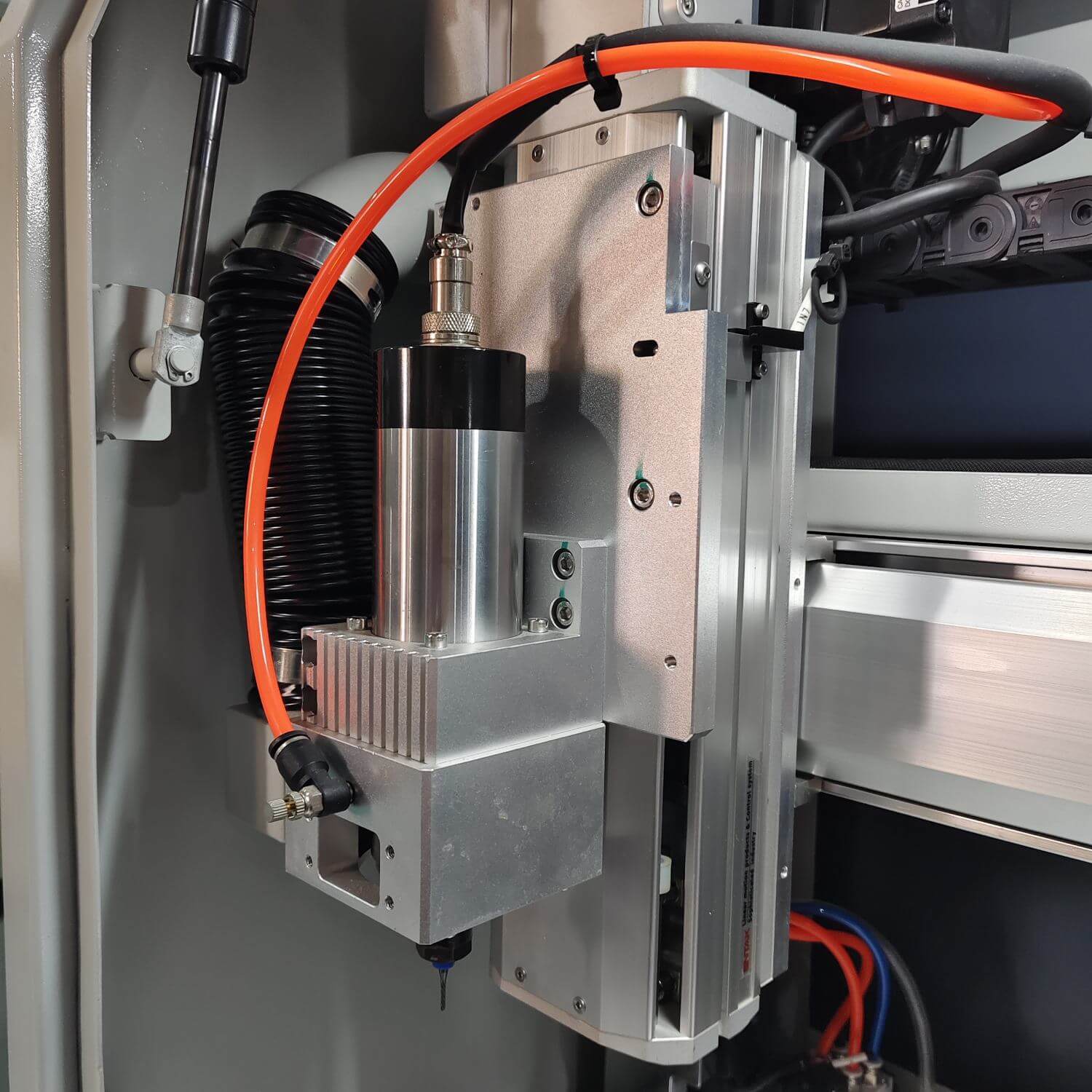

Specialized for PCB routing, this depaneler is engineered to minimize thermal stress. It prevents heat-related damage to delicate PCB components and solder joints during processing, ensures precise, clean routing results, reduces rework risks, boosts processing stability, and optimizes PCB manufacturing workflows reliably.

|

Model

|

RS-500

|

RS-500L

|

|

Machine Dimension

|

1240x1050x1450mm(L*W*H)

|

1380x1591xX1450(L*W*H)

|

|

Effective Cutting Dimension

|

350x380mm(L*W)

|

450x600mm(L*W)

|

|

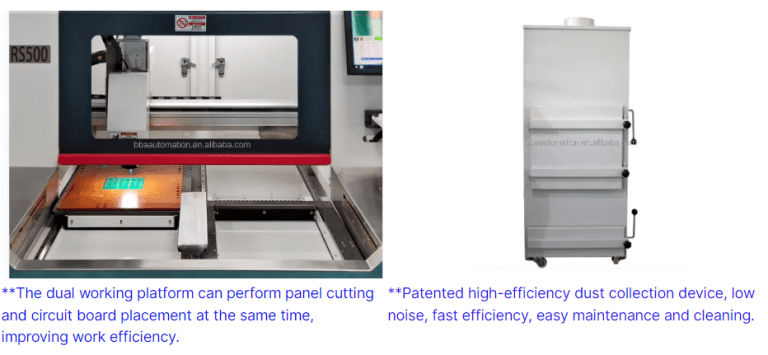

Working Platform

|

Double

|

Double

|

|

Machine Repeatability Accuracy

|

±0.01mm

|

±0.01mm

|

|

Cutting Accuracy

|

±0.05mm

|

±0.05mm

|

|

Maximum Movement Speed

|

XY:1000mm/s Z:300mm/s

|

XY:1000mm/s Z:300mm/s

|

|

Maximum Movement stroke

|

X :750mm, Y:510mm, Z :100 mm

|

X:750mm, Y :510mm, Z:100mm

|

|

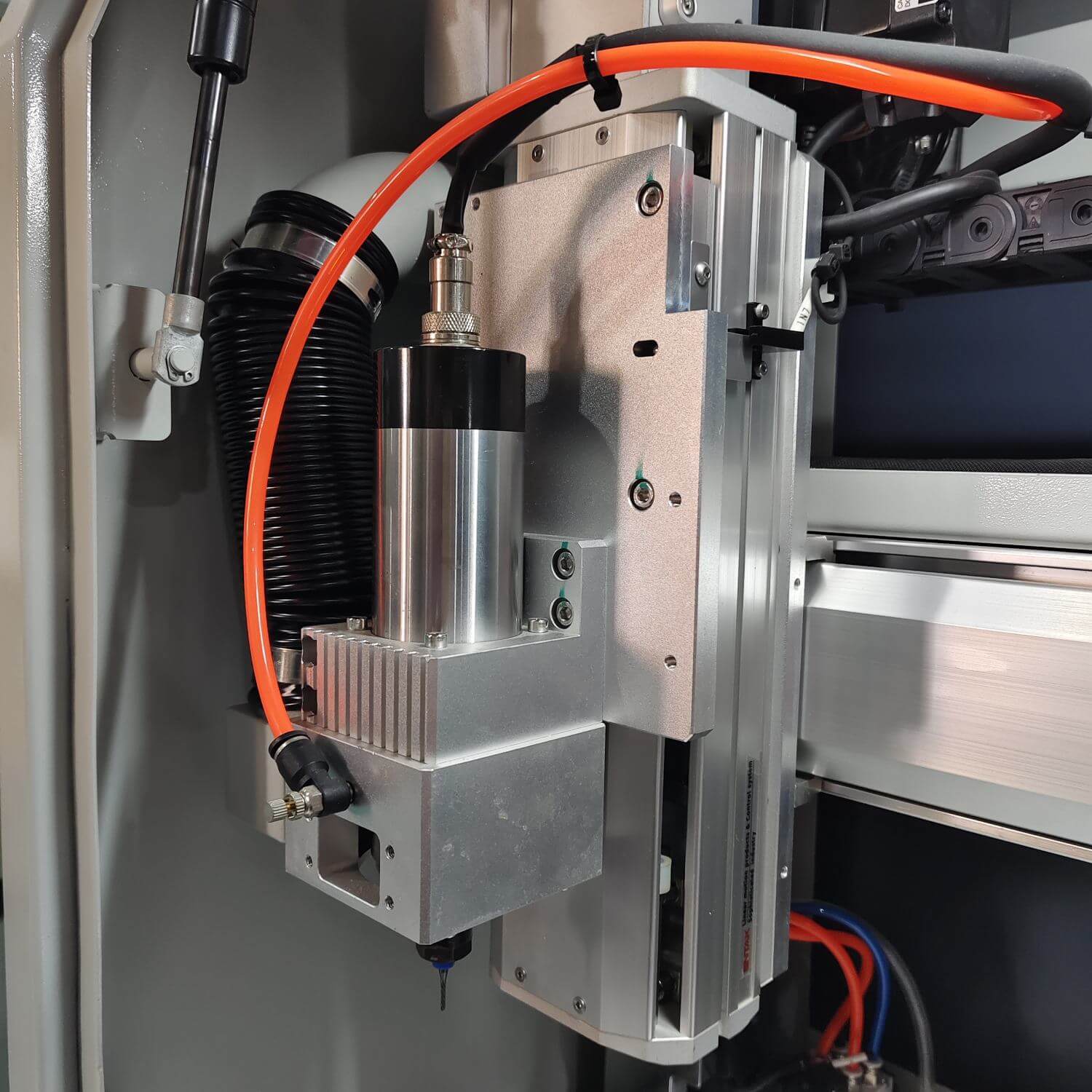

Spindle Rotating speed

|

MAX.60000RPM (adjustable)

|

MAX.60000RPM (adjustable)

|

|

Milling cutter replacement method

|

Manual replacement (Default)/ Automatic replacement (Optional)

|

Manual replacement (Default)/ Automatic replacement (Optional)

|

|

Cutting Speed

|

1~100mm/s (adjustable)

|

1~100mm/s (adjustable)

|

|

Operation Interface

|

Window10 system operation interface

|

Window10 system operation interface

|

|

Programming Method

|

Color CCD image visual teaching input

|

Color CCD image visual teaching input

|

|

Program Backup

|

one click recovery

|

one click recovery

|

|

XYZ Axis Drive Mode

|

AC servo motor

|

AC servo motor

|

|

Dust Vacuum Machine Power

|

Upwards vacuum 4P (3KW)

Upwards vacuum 6P (3KW)

Downwards vacuum 3HP (2.2KW)

Downwards vacuum 5HP (3.75KW)

|

Upwards vacuum 4P (3KW)

Upwards vacuum 6P (3KW)

Downwards vacuum 3HP (2.2KW)

Downwards vacuum 5HP (3.75KW)

|

Product Description