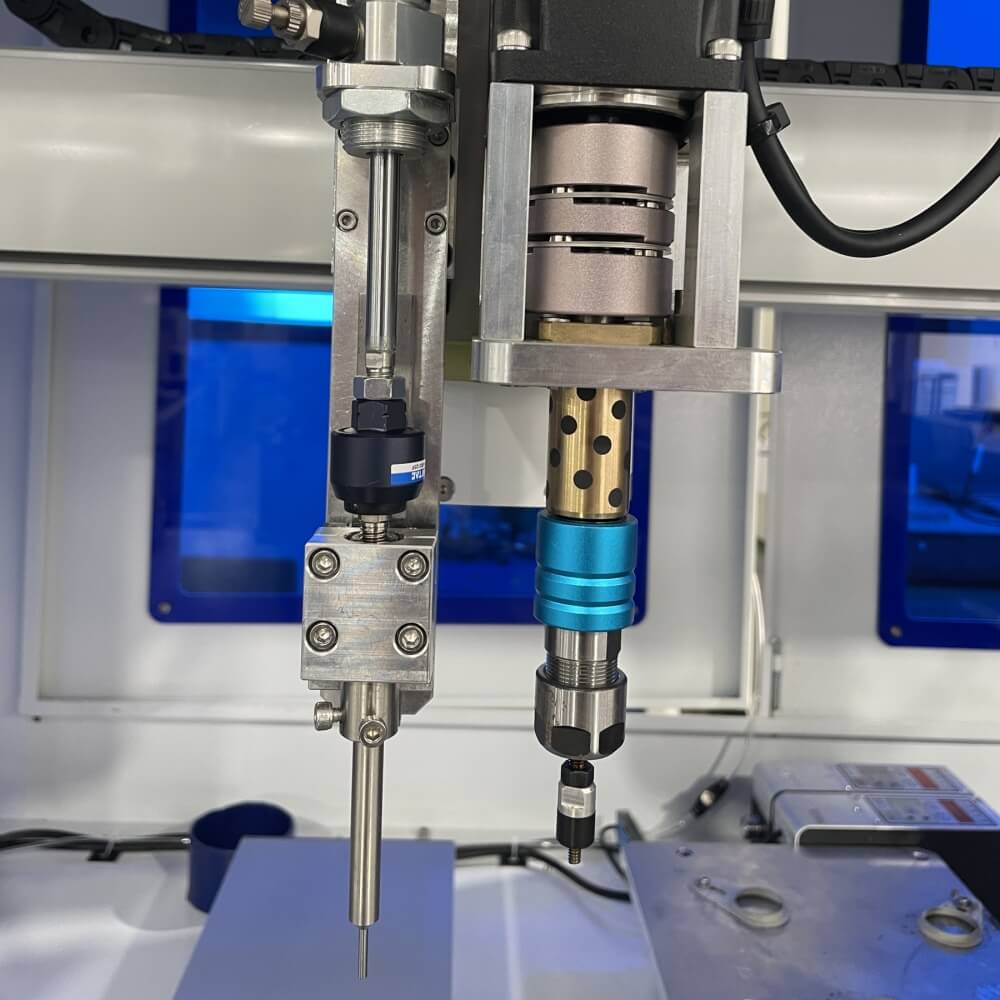

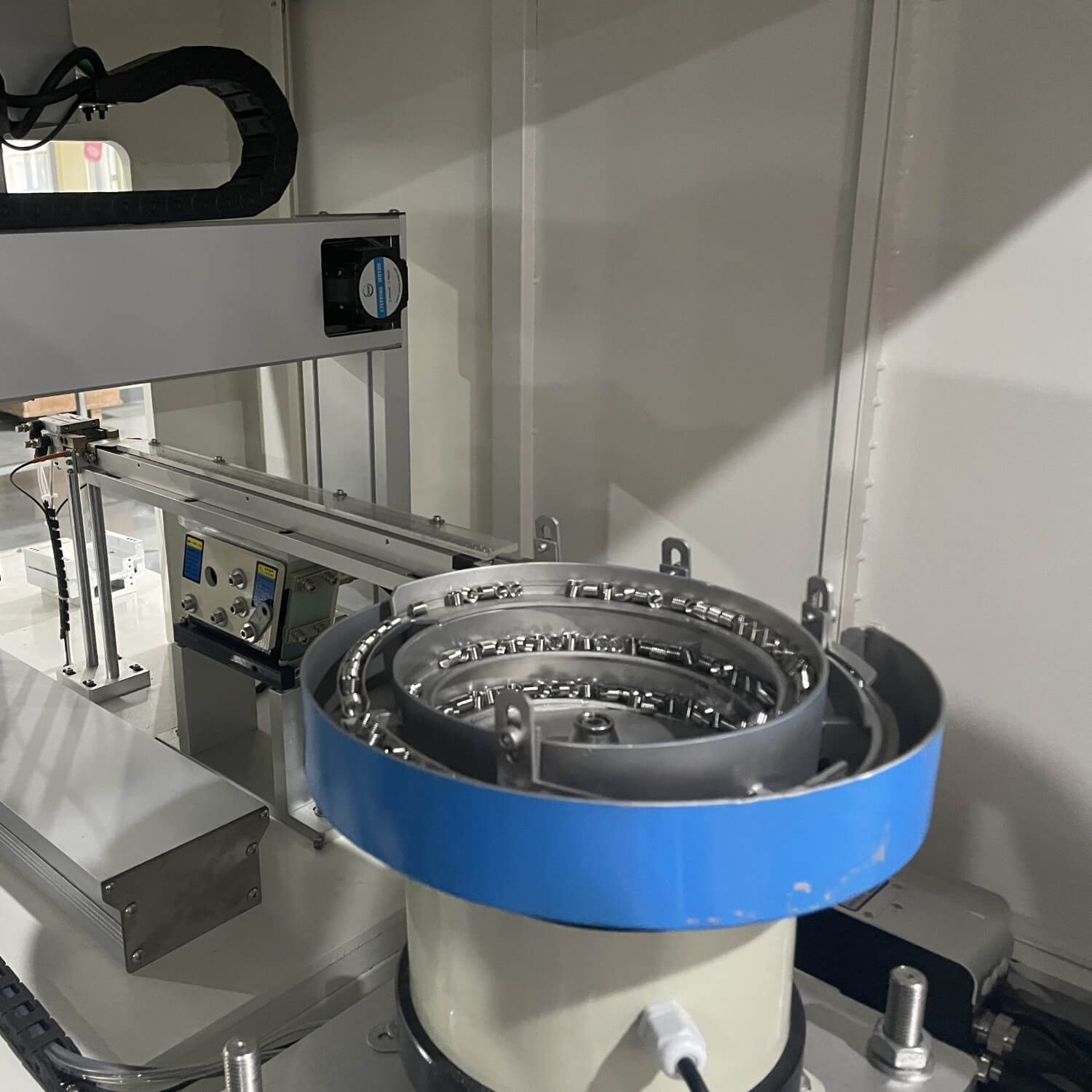

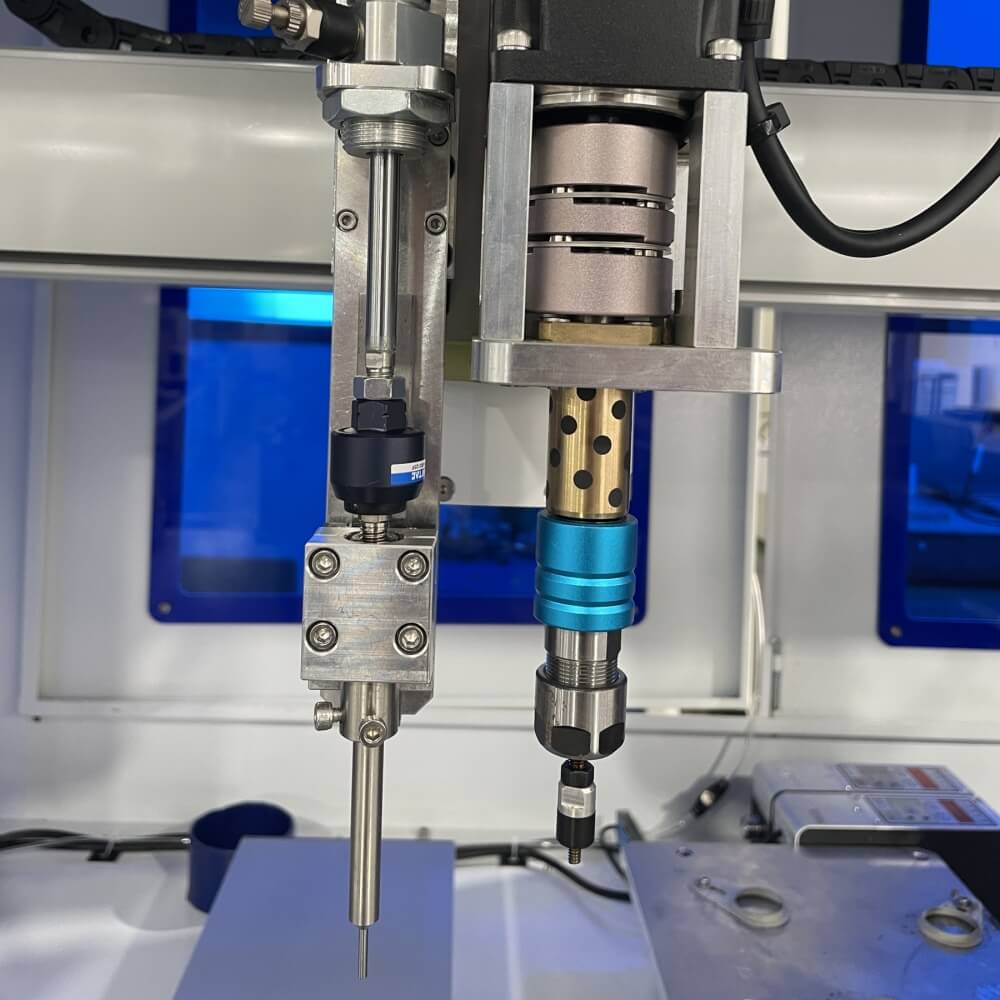

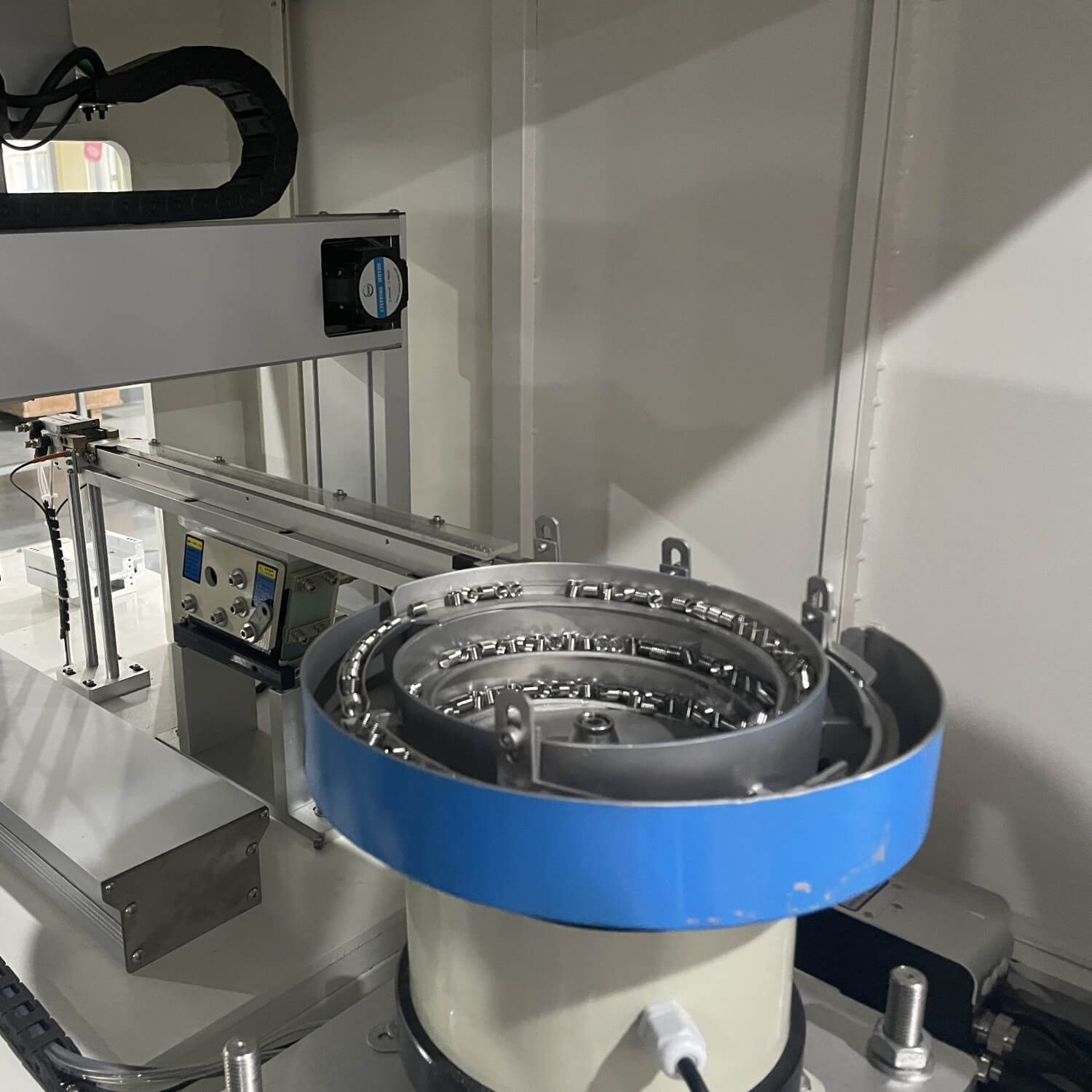

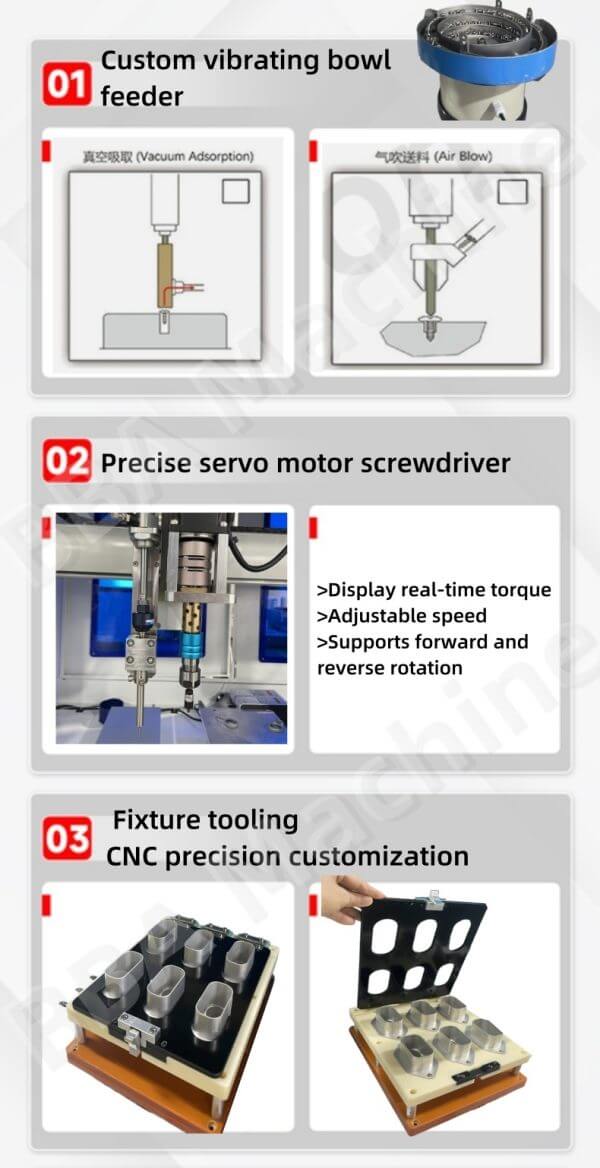

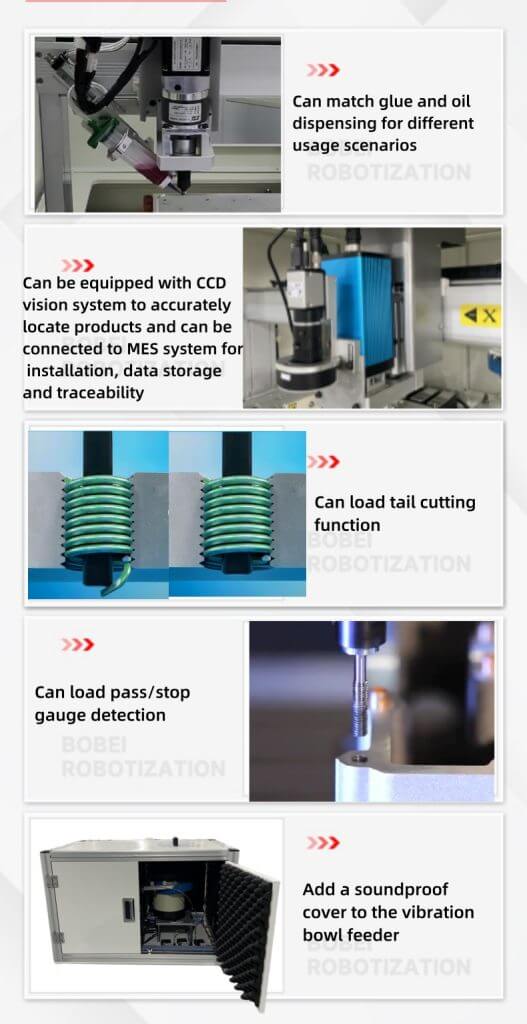

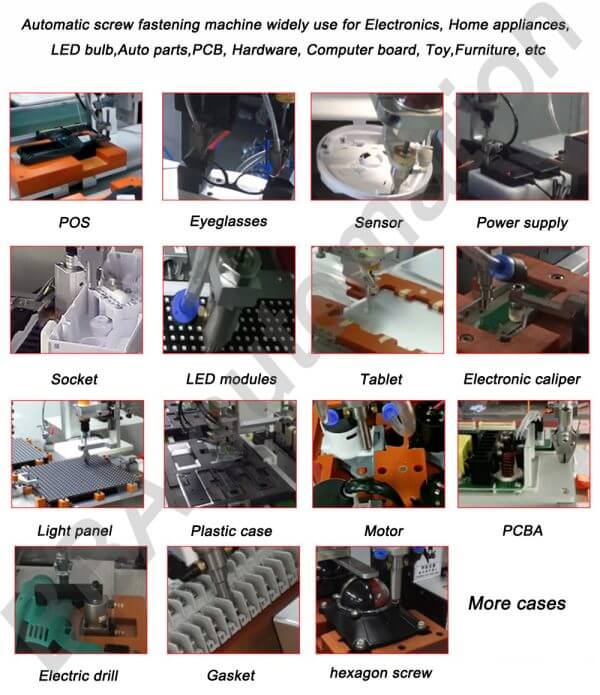

This overview spotlights key features of coil insert installation equipment, enabling accurate, fast, and reliable thread insert installation. It emphasizes adaptability to diverse materials and global industries, ensuring consistent results, cutting processing time, and meeting varied industrial thread reinforcement needs.

| Voltage | AC110/220V 50/60HZ |

| Power | 1000W |

| Stroke | 500*400*400*100mm (X*Y*Z), can be customized |

| Movement speed | 10-500mm/S |

| Position accuracy | ±0.05mm/axis |

| Universal screw thread | M3-M10 |

| Screw thread height | 6-20mm |

| Screw thread material | Copper, Aluminum, Metal, Stainless steel |

| Screw thread type | Self-tapping thread, screw thread, steel thread |

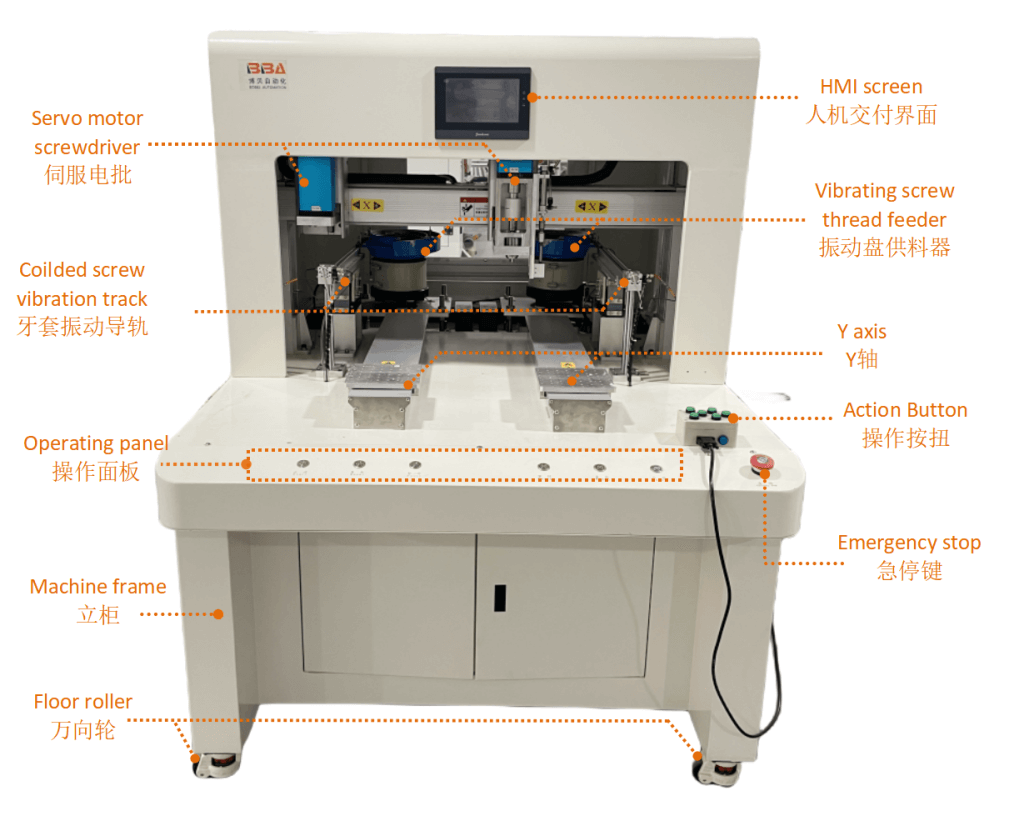

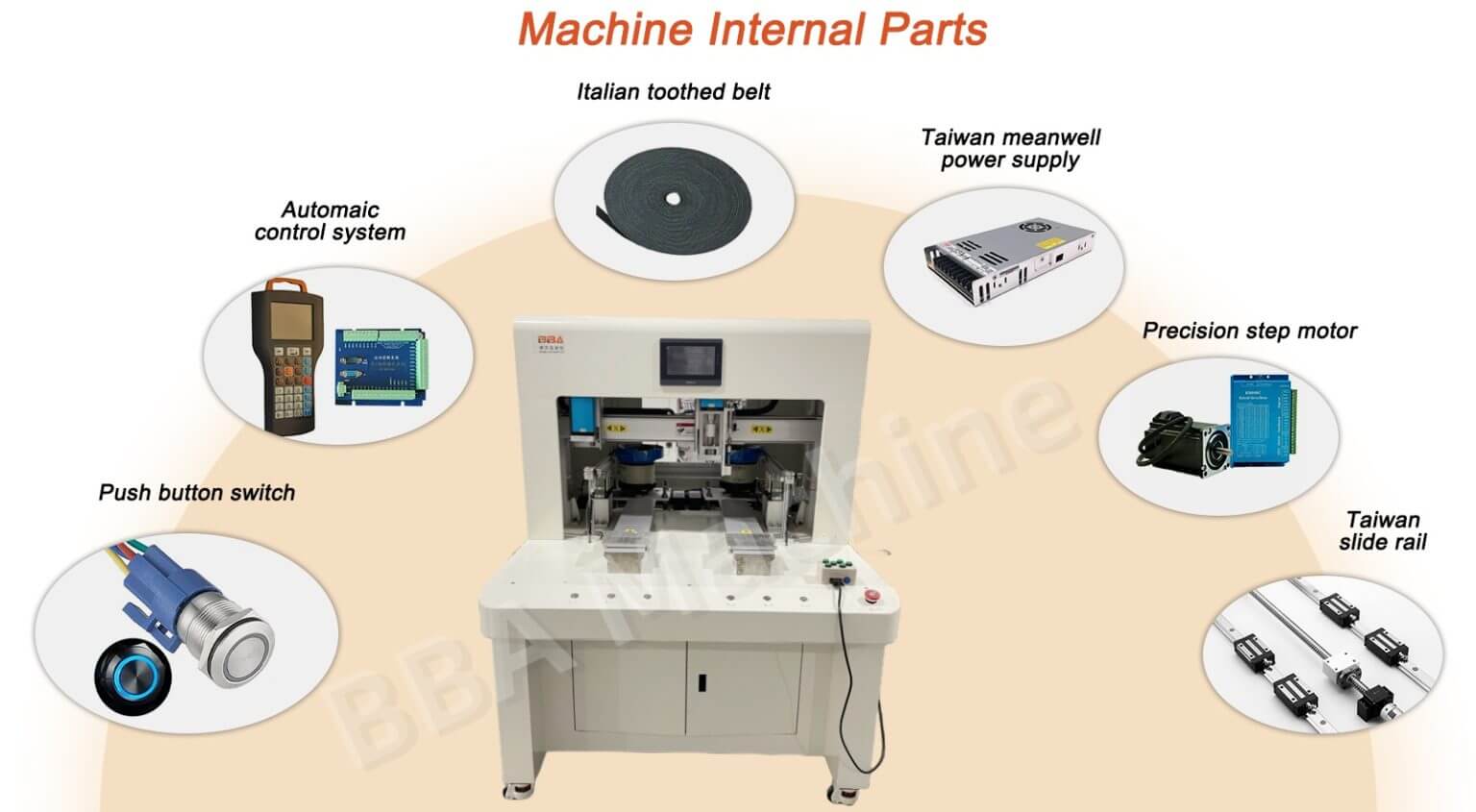

| Transmission mode | Precision toothed belt+guide rail |

| Control panel | PLC+HMI screen |

| Conveying mode | Vibrating plate+direct vibrating track |

| Work efficiency | 6S/pcs (include cutting thread tail), details depends on thread size |

| Air pressure | 0.4-0.6Mpa |

| External port | RS232 |

| Program capacity | 12 groups, 20 points per group; can be customized |

| Work environment | Temperature: 5-40℃ Humidity: 20-90% |

| Weight | 580kg(Subject to the actual product) |

| External machine size (L*W*H) | 1150*1350*1650 mm(Can be customized) |

Product Description

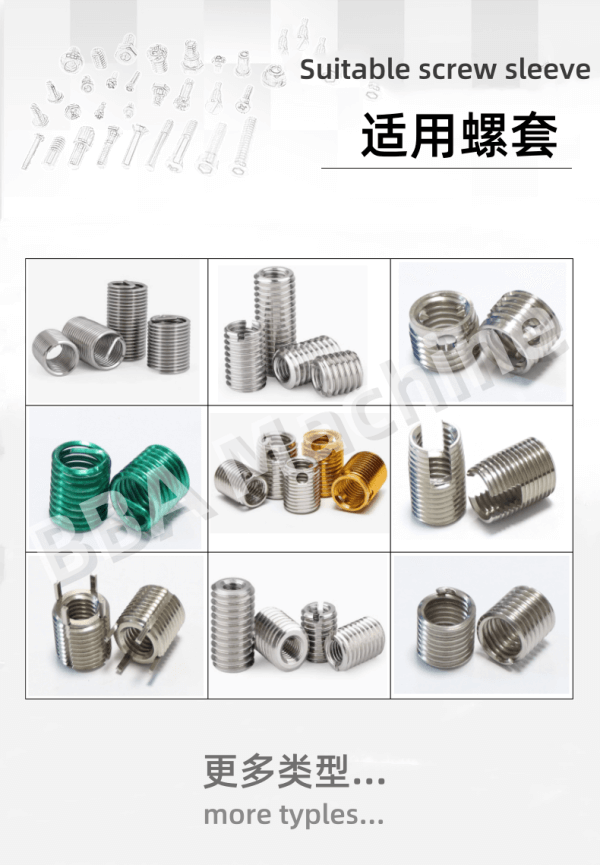

Applicable screws

Customer case

Package