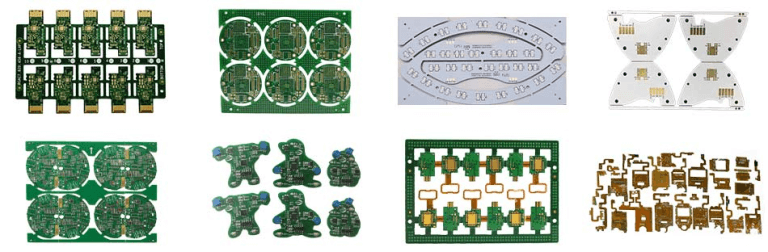

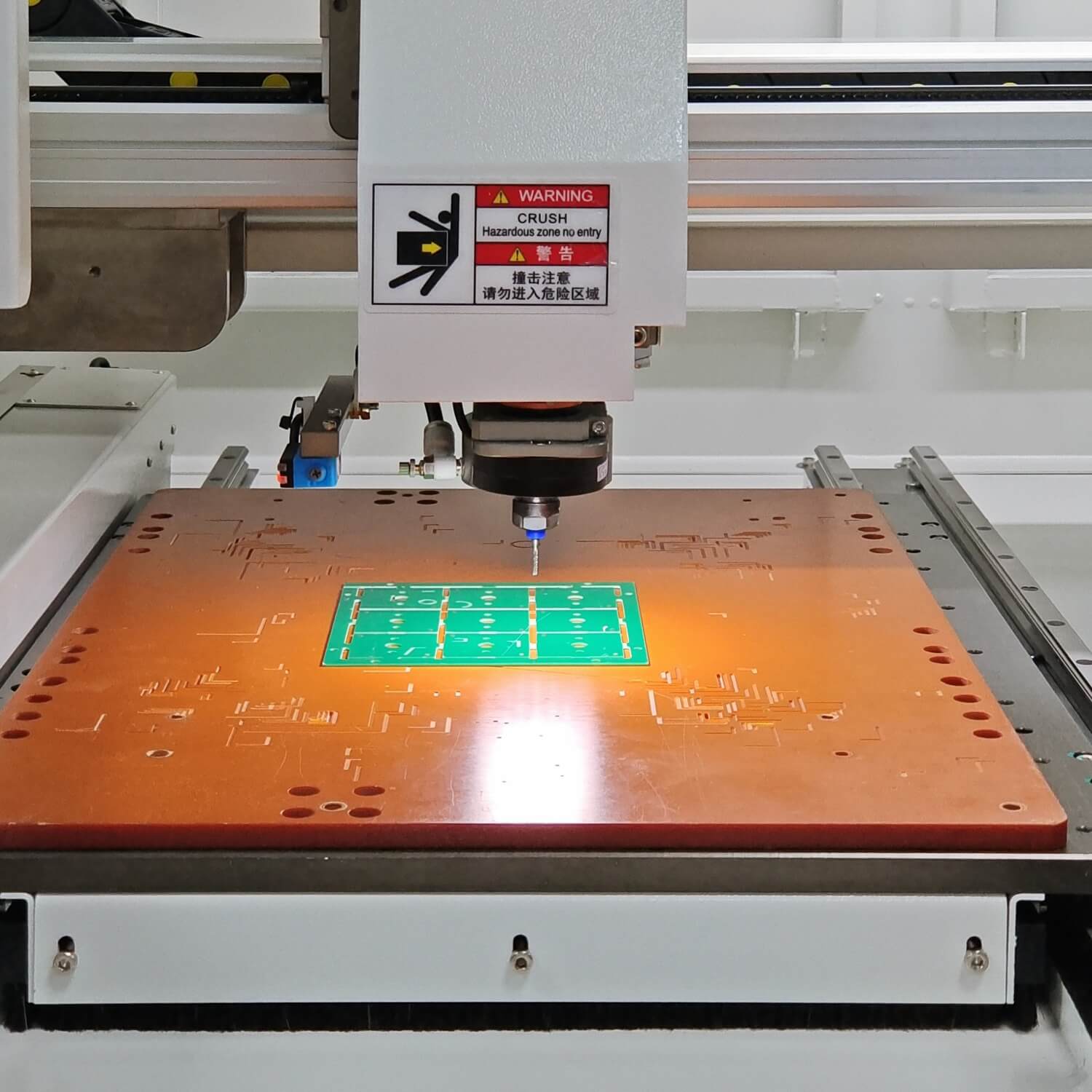

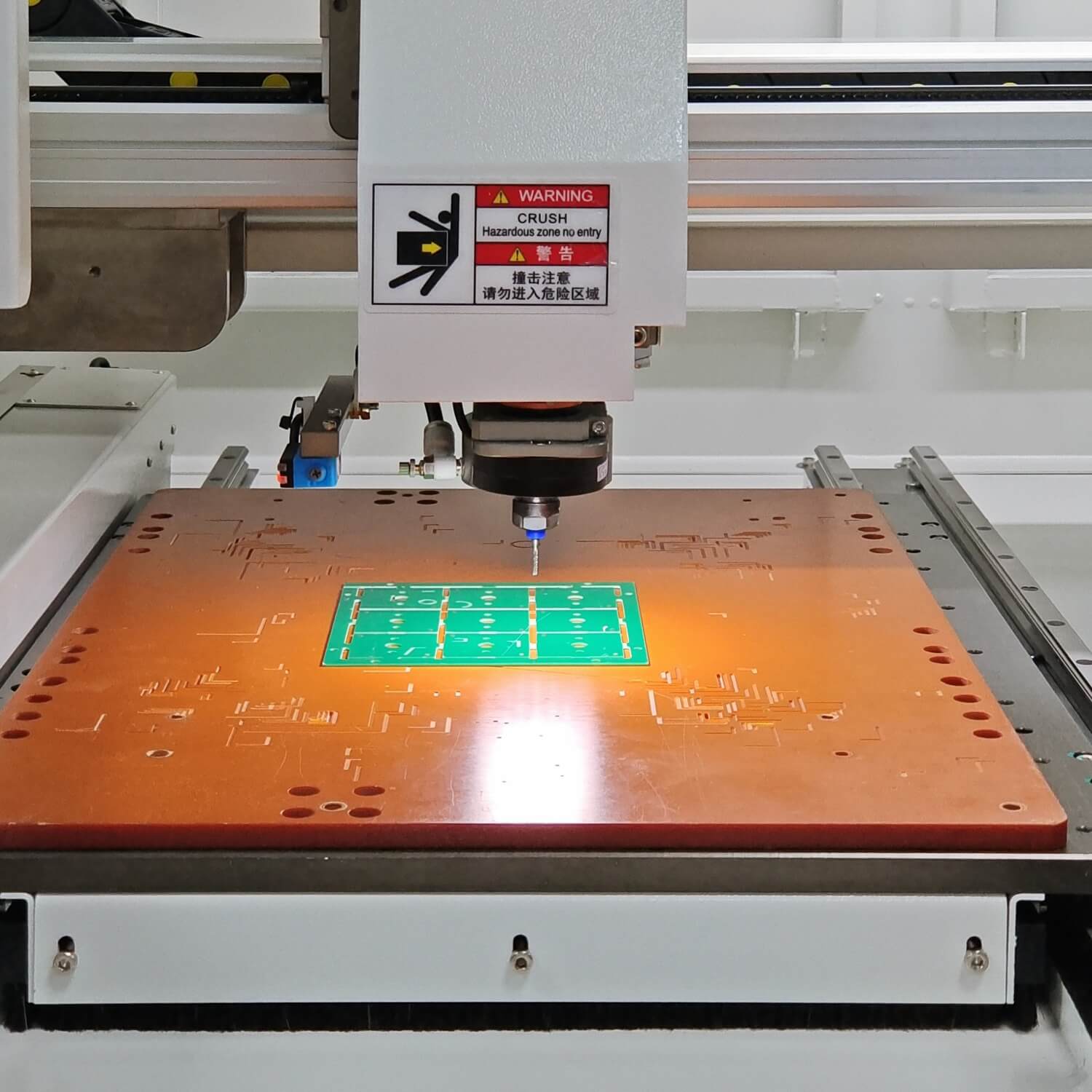

Engineered for reliable PCB depaneling, this V-Groove Depaneler features temperature-stable construction. It maintains consistent scoring performance even in fluctuating environments, ensures clean, precise V-groove cuts, avoids PCB component damage, reduces processing errors, and optimizes stable PCB manufacturing workflows.

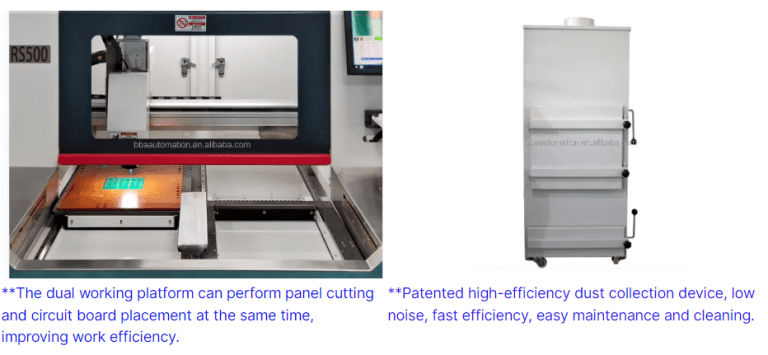

Single table cutting machine, with a maximum cutting speed of 100mm/s, adopts high-speed electric spindle, micro-stress cutting, smooth plate edge and high precision.

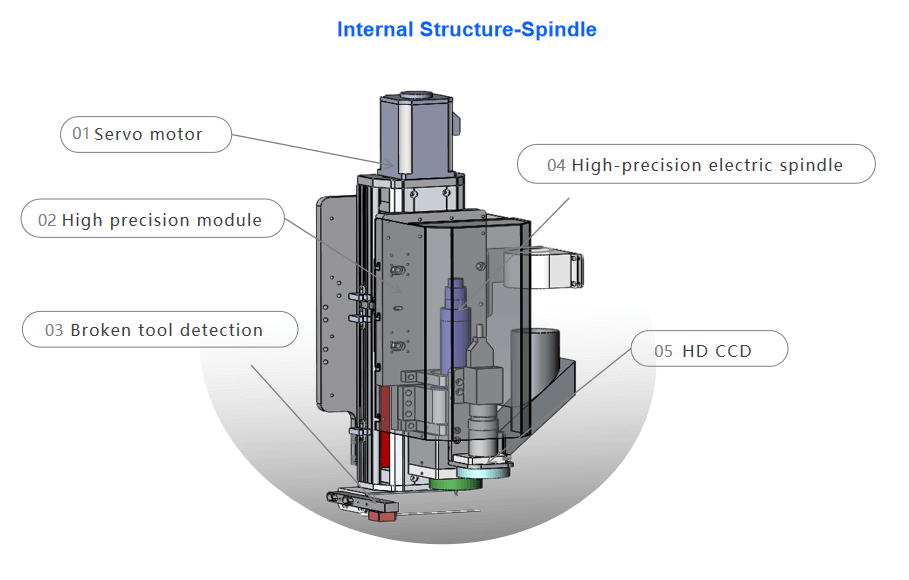

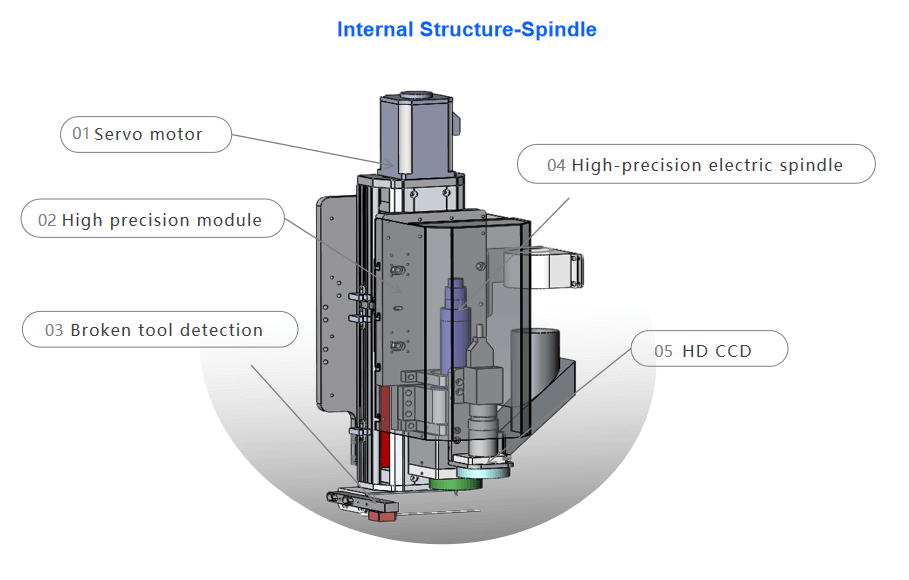

X, Y and Z axes all adopt fully enclosed modules to prevent dust and foreign matter from entering, thereby improving the life and performance of the shaft;

Using upper dust collection, built-in dust collector, small footprint

Equipped with visual system, camera tool setting, interface operation, simple and convenient, ensuring accurate alignment.

Optional barcode reading function, realizes 1D/2D barcode reading and saving or uploading, which is convenient for traceability and digital management.

| Item | RS-100N |

| Main Equipment Size | 680x1050x1450mm(L*W*H) |

| Effective Cutting Dimension | 340x380mm(L*W) |

| Processing Platform | Single Platform |

| Machine Repeatability Accuracy | ±0.01mm |

| Cutting Accuracy | ±0.05mm |

| Maximum Movement Speed | XY:1000mm/s,Z:300mm/s |

| Maximum Movement | X:385mm Y:510mm Z:100mm |

| Spindle Rotating speed | MAX:60000RPM,Adjustable |

| Milling cutter replacement method | Manual replacement/Automatic replacement |

| Cutting Speed | 1~100mm/s ,Adjustable |

| Operation Interface | Visual Operation Window |

| Programming Method | Color CCD image didactic input,offline programming |

| Program Backup | Key Restore |

| XYZ Axis Drive Mode | AC servo motor |

| Dust Vacuum Machine Power | Upwards vacuum 4P (3KW) Upwards vacuum 6P (3KW) Downwards vacuum 3HP (2.2KW) Downwards vacuum 5HP (3.75KW) |

Product Description