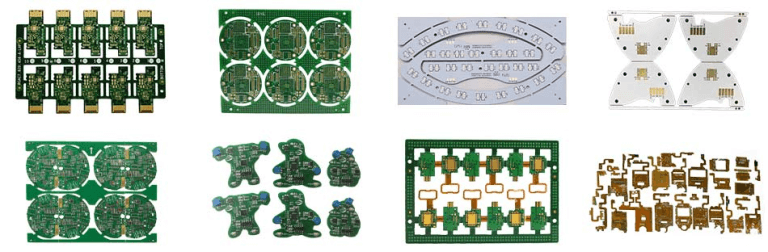

Designed for precise PCB processing, this CNC router features vision-assisted origin finding. It enables repeatable routing accuracy, quickly locates PCB origins to avoid misalignment, protects delicate circuit boards, boosts processing efficiency, reduces errors, and optimizes PCB manufacturing workflows reliably.

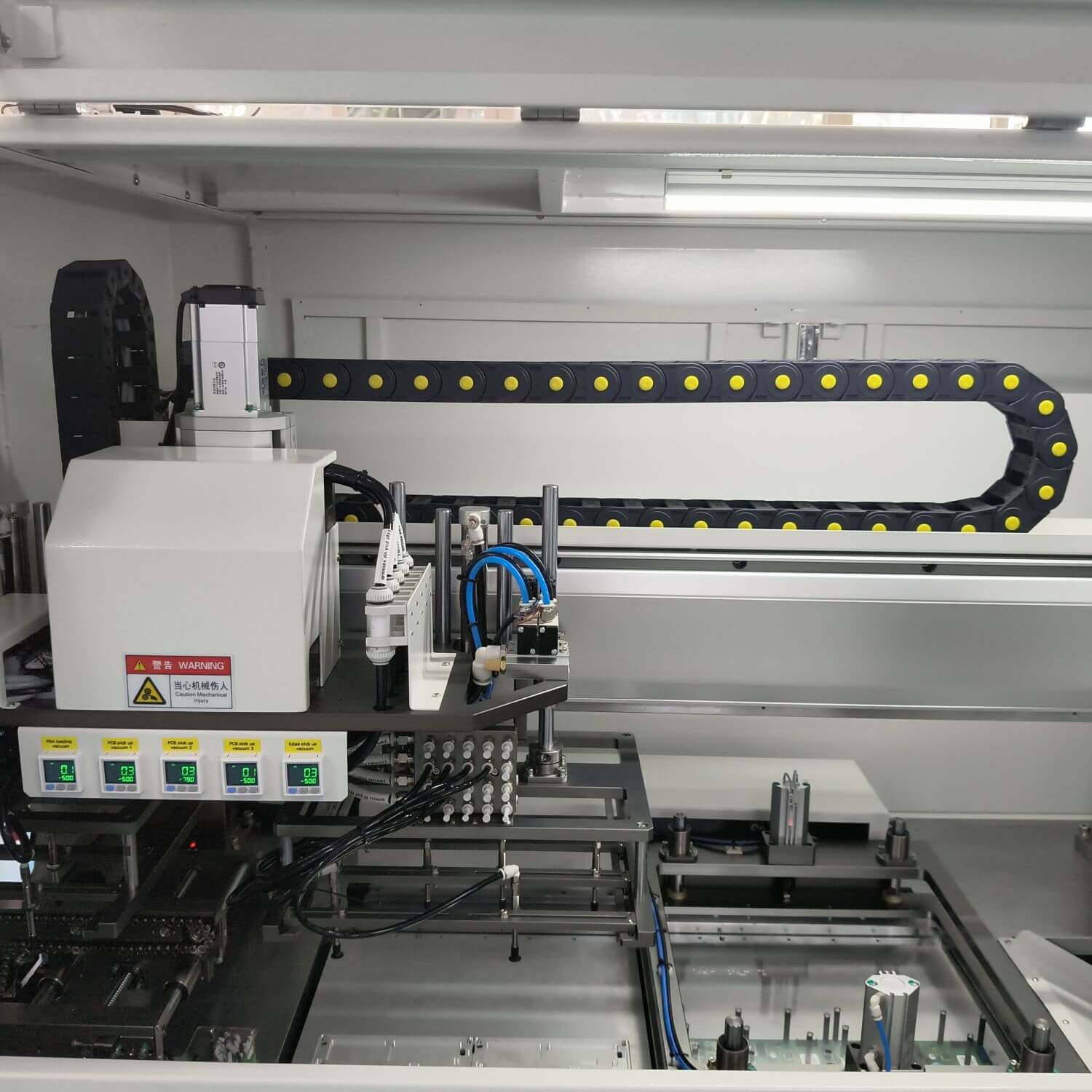

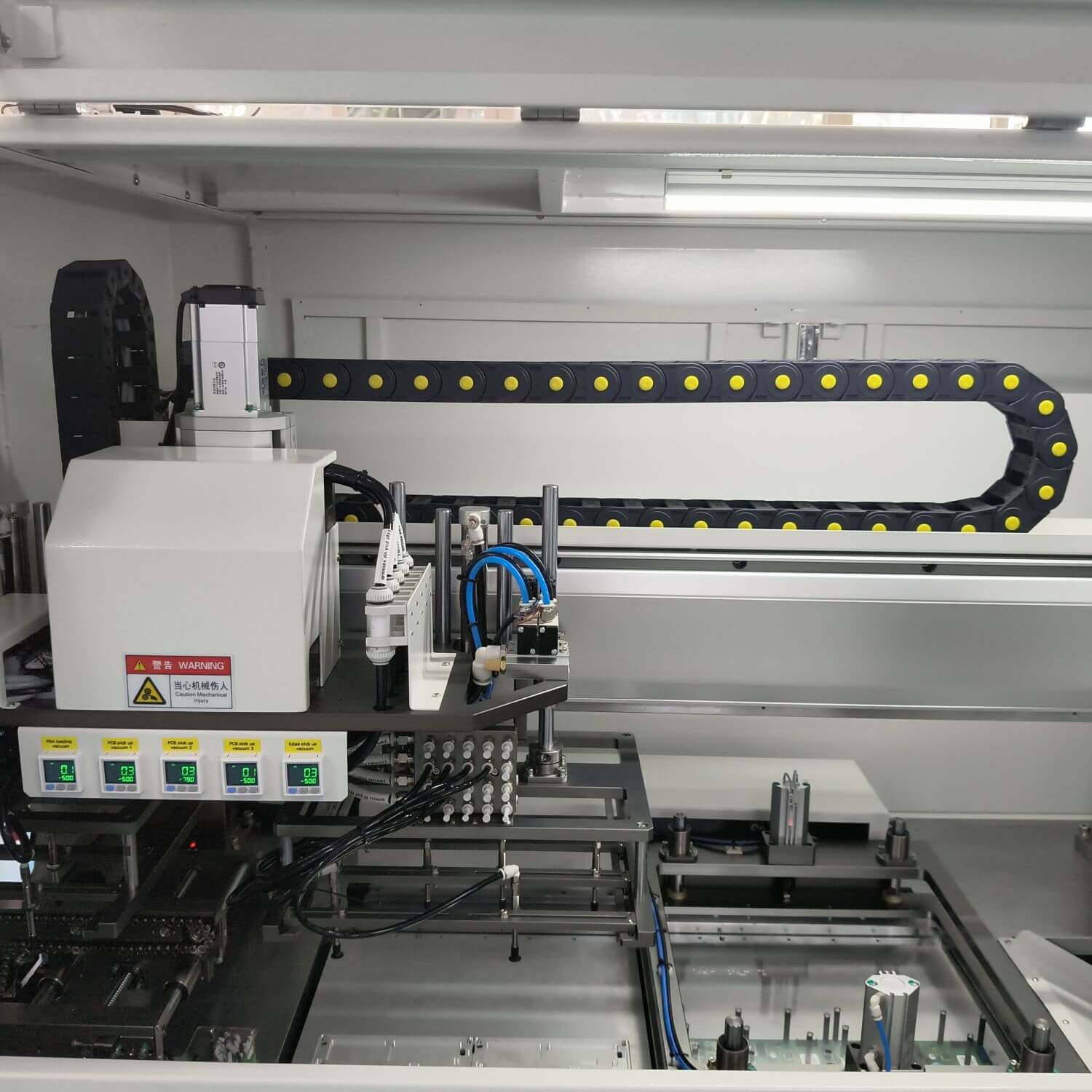

1. All the moving axes of this equipment adopt high-precision modules, which are high-precision and beautiful.

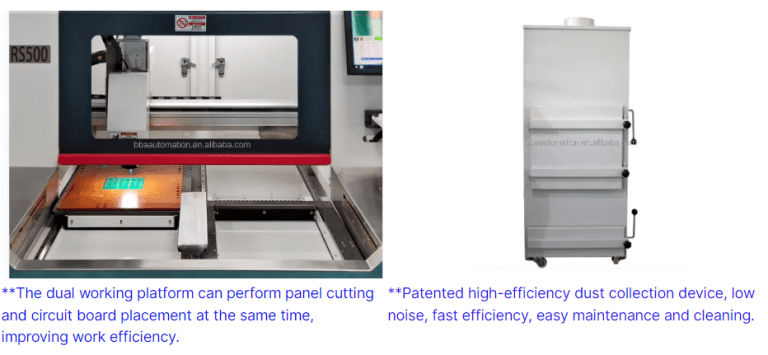

2. The automatic board separation mechanism adopts a precision module equipped with a high-definition CCD module, which has a dust suction function. It is equipped with a broken knife detection function as standard, and can be upgraded to an automatic knife change function.

3. The loading and unloading mechanism of the manipulator adopts a vacuum adsorption method, and is equipped with a high-vacuum combined vacuum component and a suction cup quick adjustment structure. It has strong versatility, is easy to adjust, and is more convenient to replace products.

| Item | RS-100N |

| Main Equipment Size | 680x1050x1450mm(L*W*H) |

| Effective Cutting Dimension | 340x380mm(L*W) |

| Processing Platform | Single Platform |

| Machine Repeatability Accuracy | ±0.01mm |

| Cutting Accuracy | ±0.05mm |

| Maximum Movement Speed | XY:1000mm/s,Z:300mm/s |

| Maximum Movement | X:385mm Y:510mm Z:100mm |

| Spindle Rotating speed | MAX:60000RPM,Adjustable |

| Milling cutter replacement method | Manual replacement/Automatic replacement |

| Cutting Speed | 1~100mm/s ,Adjustable |

| Operation Interface | Visual Operation Window |

| Programming Method | Color CCD image didactic input,offline programming |

| Program Backup | Key Restore |

| XYZ Axis Drive Mode | AC servo motor |

| Dust Vacuum Machine Power | Upwards vacuum 4P (3KW) Upwards vacuum 6P (3KW) Downwards vacuum 3HP (2.2KW) Downwards vacuum 5HP (3.75KW) |

Product Description