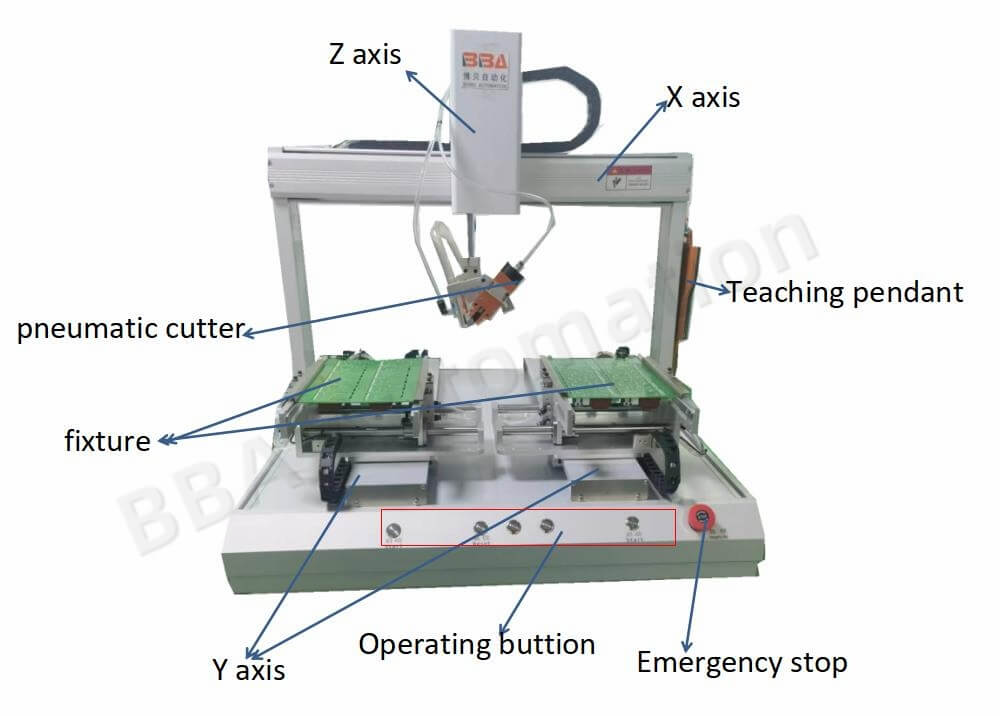

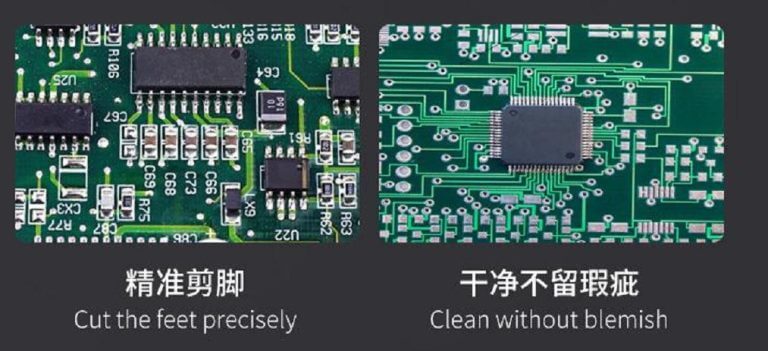

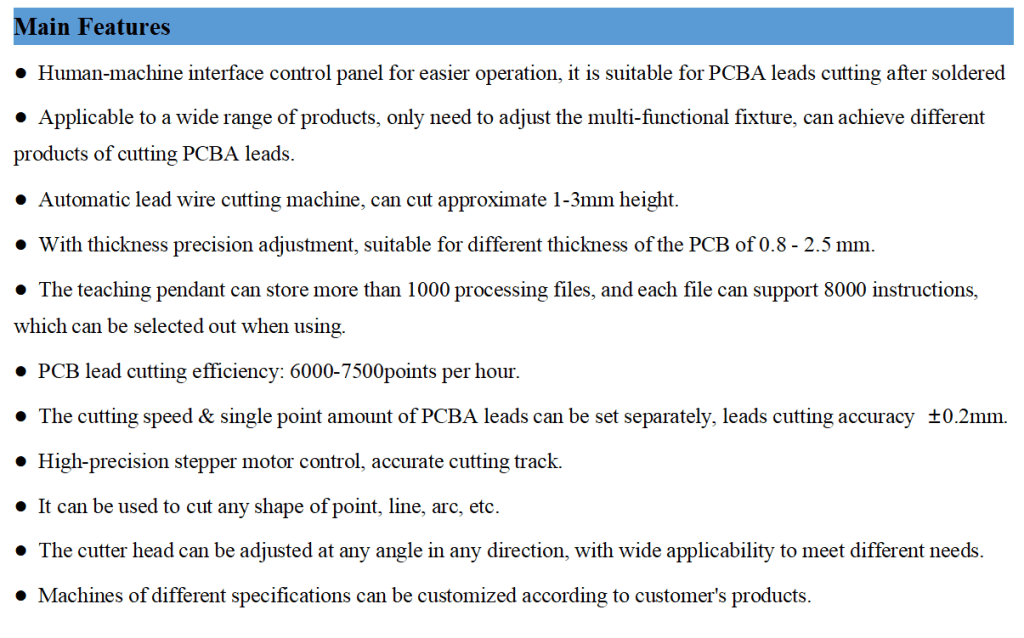

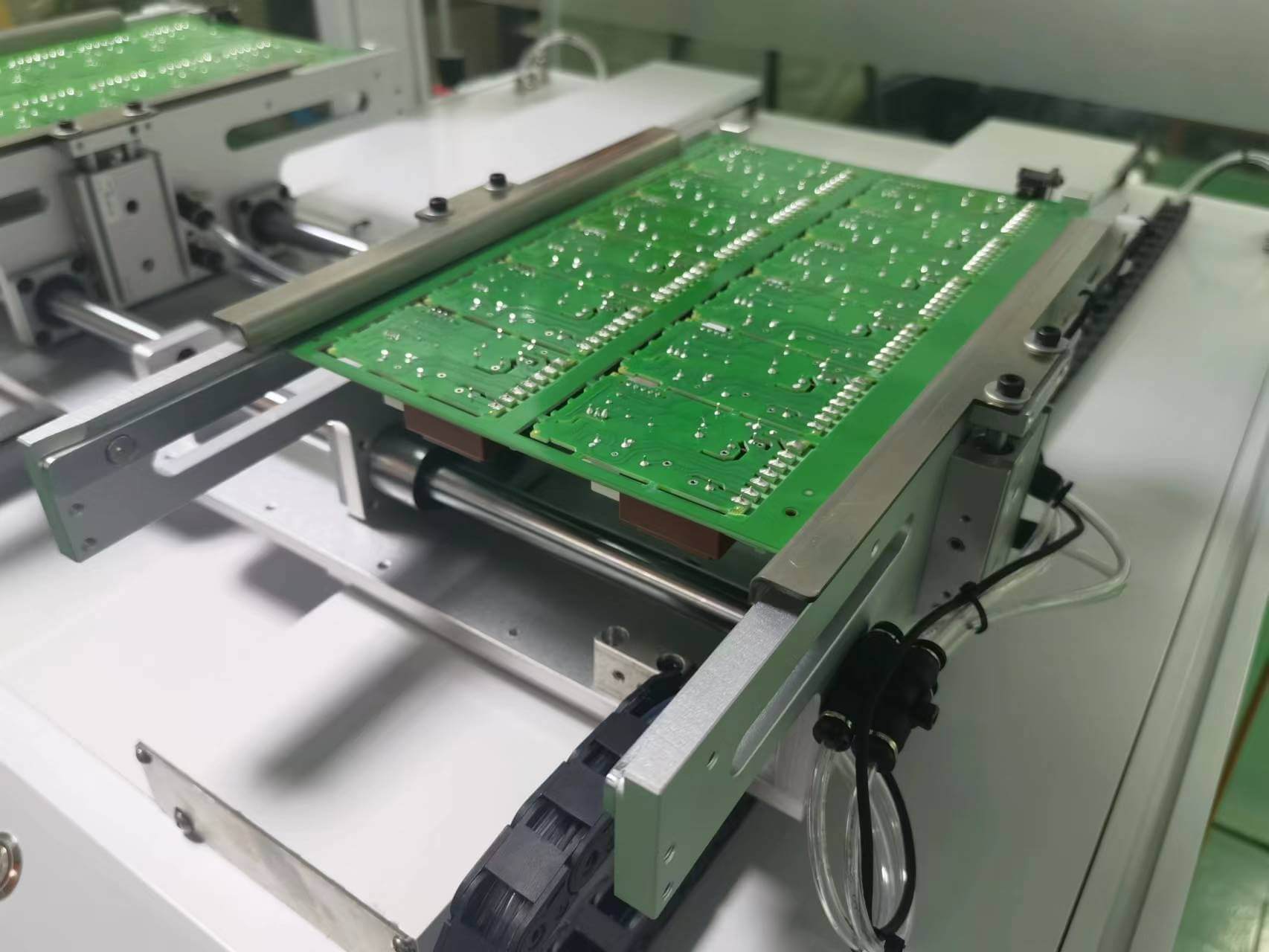

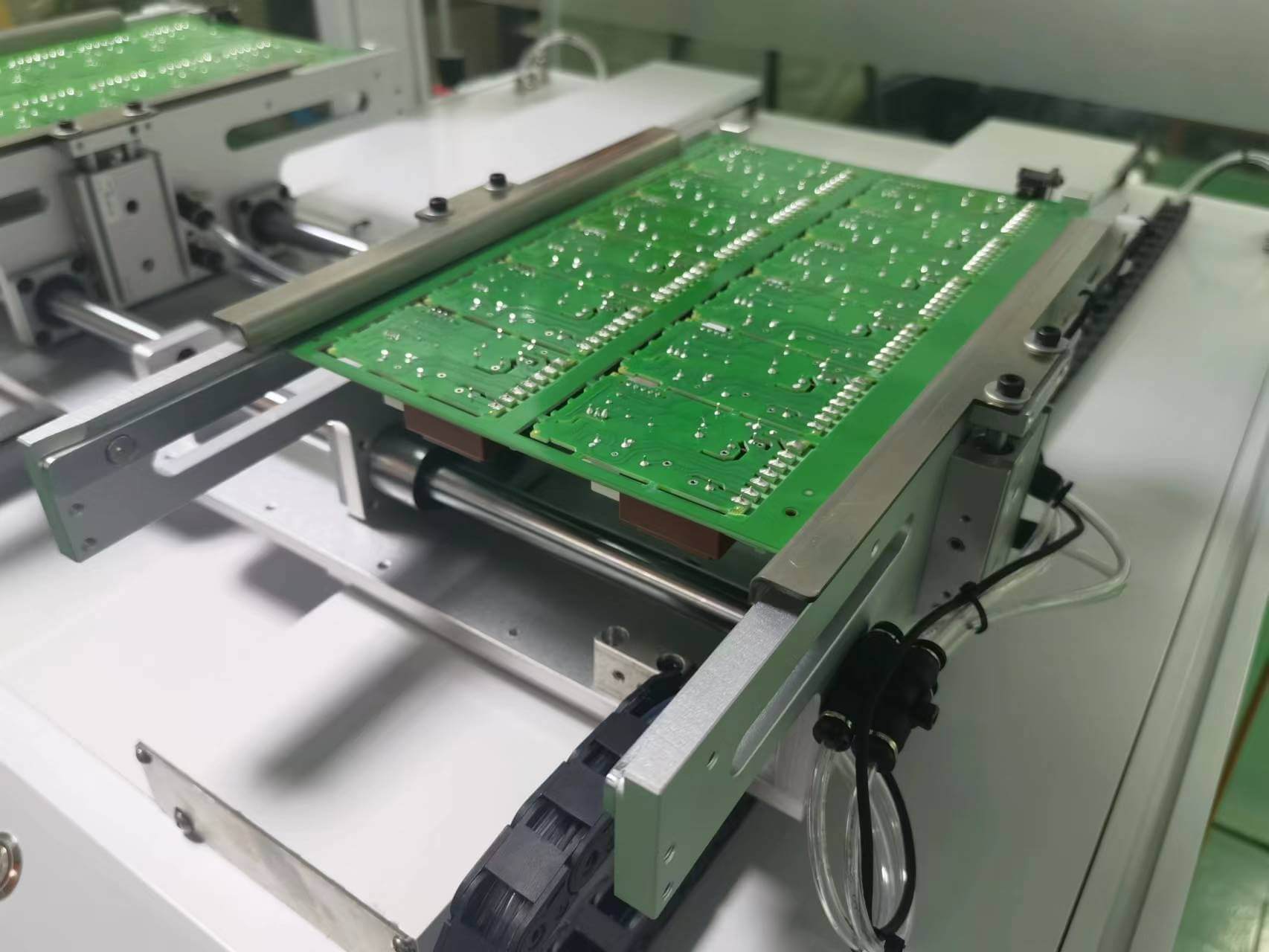

Tailored for PCB assembly, this automatic equipment handles both lead and pin cutting. It delivers efficient, precise trimming to meet assembly needs, eliminates manual cutting errors, reduces rework, boosts workflow speed, ensures consistent results, and provides reliable solutions for PCB lead/pin processing.

|

Model

|

BBA-331CU

|

BBA-5331CU

|

BBA-6331CU

|

BBA CUSTOMIZED

|

|||

|

(Single Y platform)

|

(Dual Y platforms)

|

(Dual cutting systems)

|

|||||

|

Voltage

|

AC 110/220V 50/60HZ

|

||||||

|

Power

|

350W

|

350W

|

700W

|

To order

|

|||

|

Movable range

|

X

|

300mm

|

X

|

500mm

|

X

|

600mm

|

To order

|

|

Y

|

300mm

|

Y1/Y2

|

300mm

|

Y1/Y2

|

300mm

|

||

|

Z

|

100mm

|

Z

|

100mm

|

Z

|

100mm

|

||

|

R

|

360°

|

R

|

360°

|

R

|

360°

|

||

|

Repeat Positioning Accuracy

|

±0.03mm

|

To order

|

|||||

|

Maximum Load Weight

|

10KG (For Work Platform)

|

To order

|

|||||

|

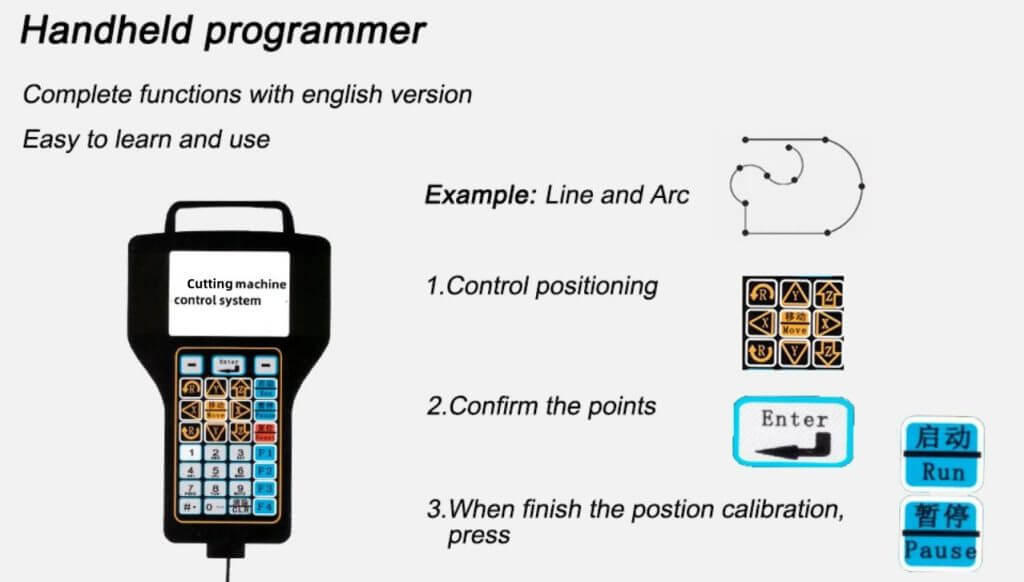

Programming File Capacity

|

1000 files, 9000 points per set

|

To order

|

|||||

|

Cutting efficiency

|

6000-7500 points per hour

|

To order

|

|||||

|

Cutting capacity

|

Copper wire ≤ Φ3.0mm (change different cutters according to wire diameters)

|

To order

|

|||||

|

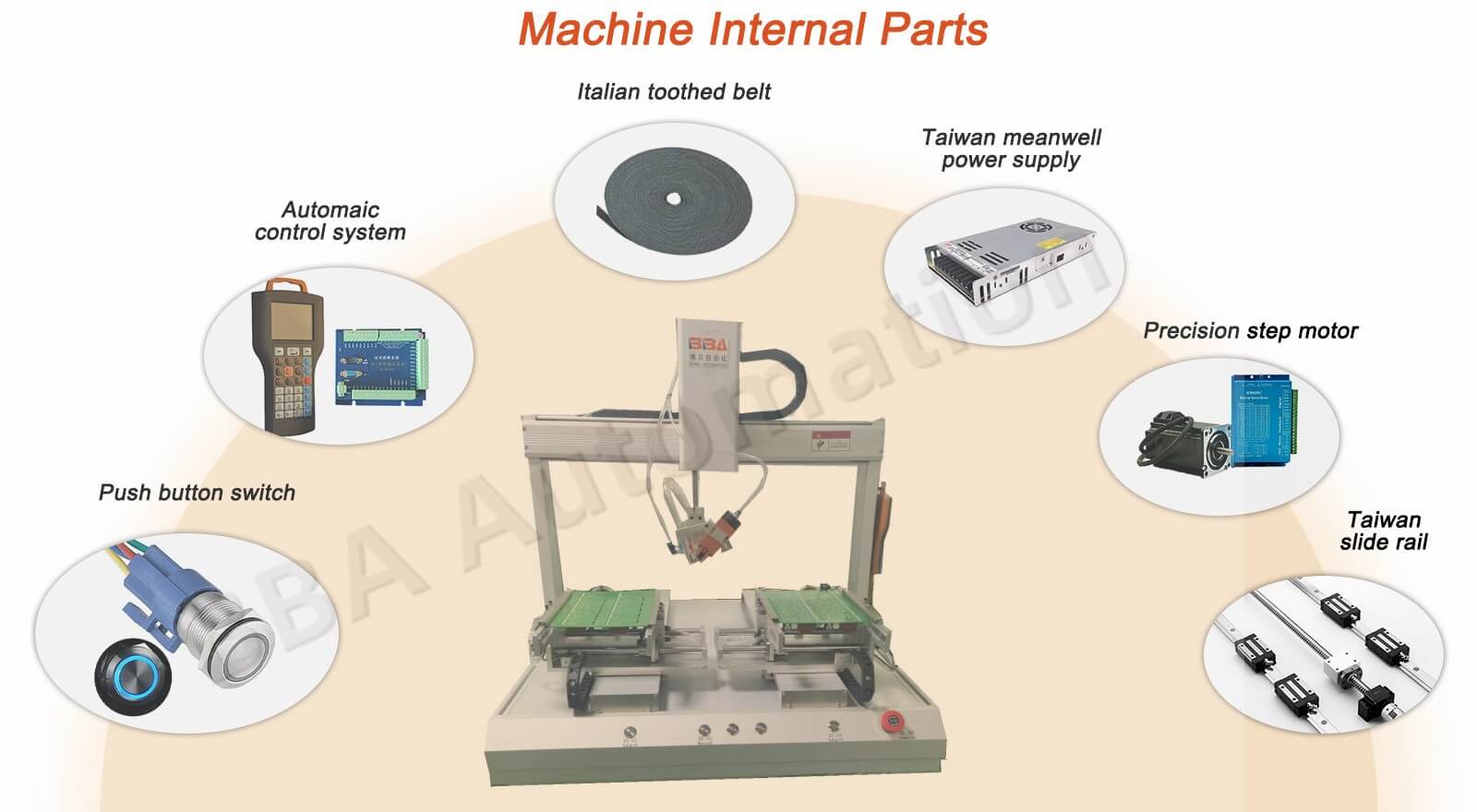

Driving mode

|

Precision stepping motor

|

To order

|

|||||

|

External Dimensions(L*W*H)

|

62*60*80(CM)

|

76*60*80(CM) |

100*60*85(CM)

|

To order

|

|||

|

Weight

|

65KG

|

80KG

|

120KG

|

To order

|

|||