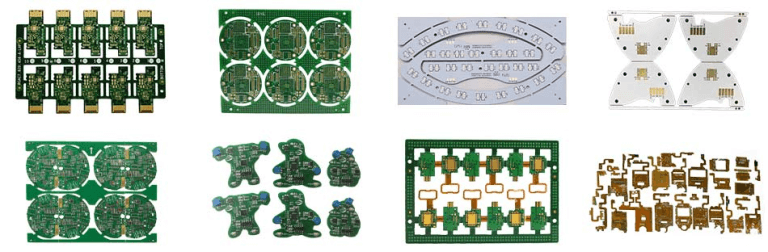

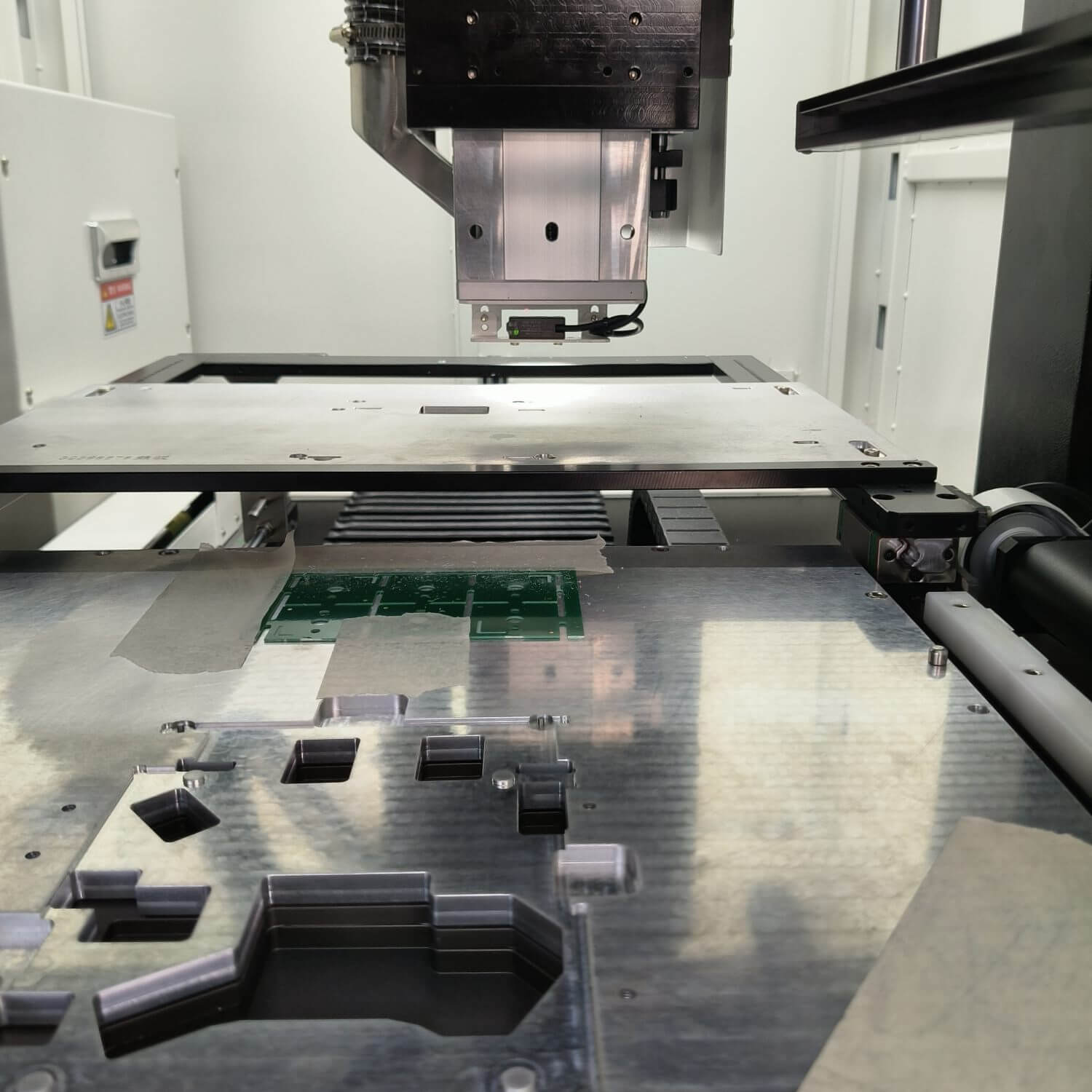

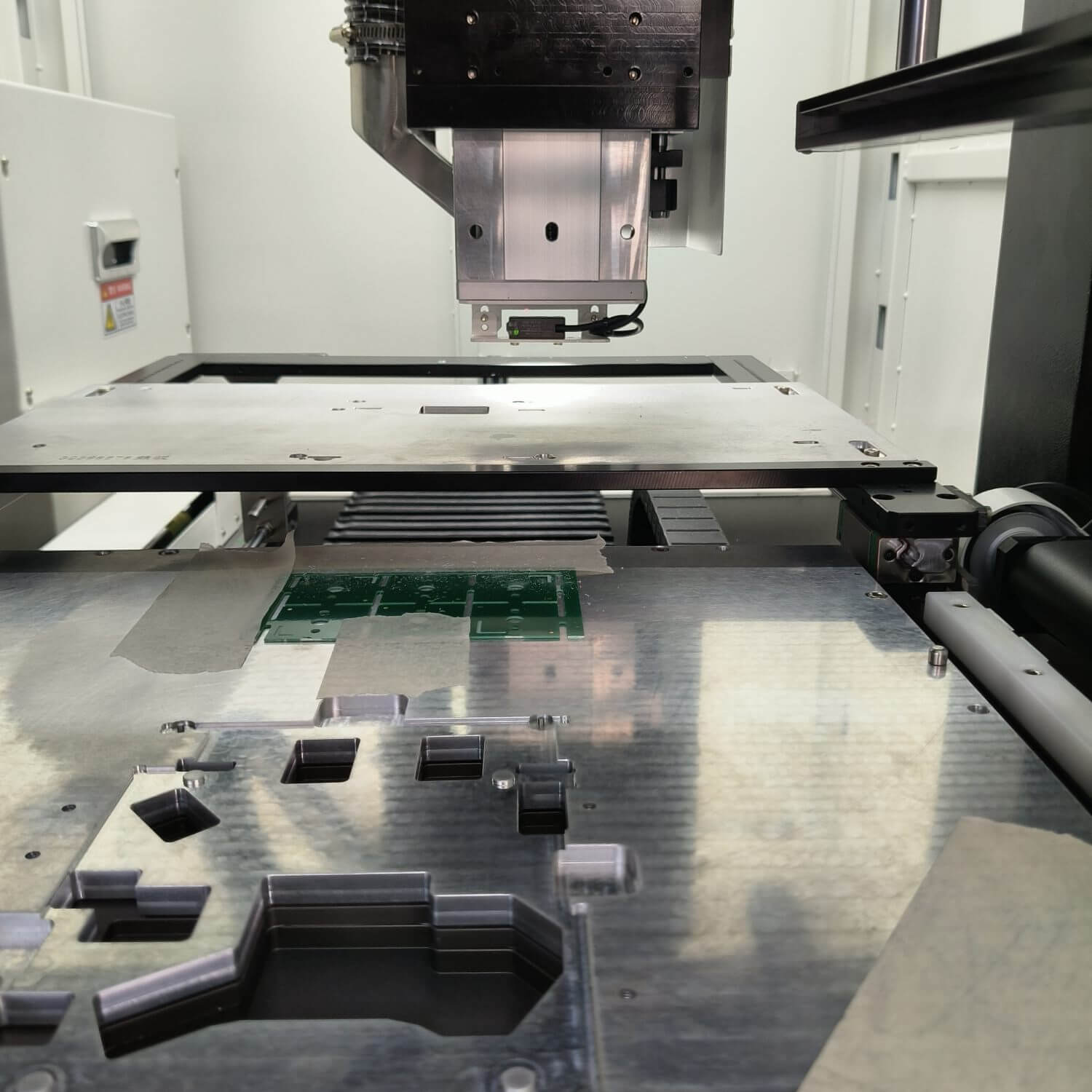

Built to protect solder joints and SMD components, this machine uses low-vibration technology for PCB depaneling. It avoids damage to delicate parts during separation, ensures clean, precise cuts, reduces rework, boosts processing efficiency, and maintains component integrity to optimize PCB manufacturing workflows.

|

Model

|

RS-500

|

RS-500L

|

|

Machine Dimension

|

1240x1050x1450mm(L*W*H)

|

1380x1591xX1450(L*W*H)

|

|

Effective Cutting Dimension

|

350x380mm(L*W)

|

450x600mm(L*W)

|

|

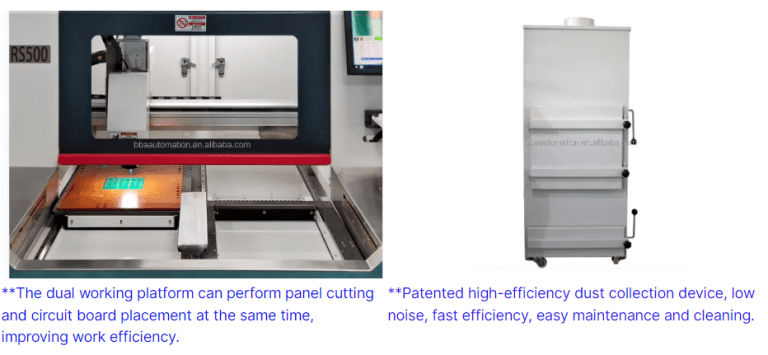

Working Platform

|

Double

|

Double

|

|

Machine Repeatability Accuracy

|

±0.01mm

|

±0.01mm

|

|

Cutting Accuracy

|

±0.05mm

|

±0.05mm

|

|

Maximum Movement Speed

|

XY:1000mm/s Z:300mm/s

|

XY:1000mm/s Z:300mm/s

|

|

Maximum Movement stroke

|

X :750mm, Y:510mm, Z :100 mm

|

X:750mm, Y :510mm, Z:100mm

|

|

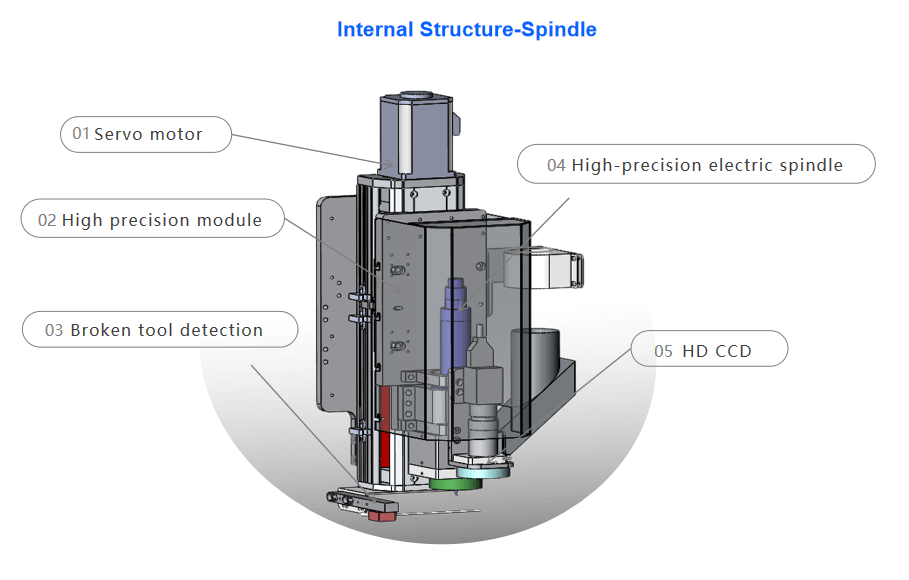

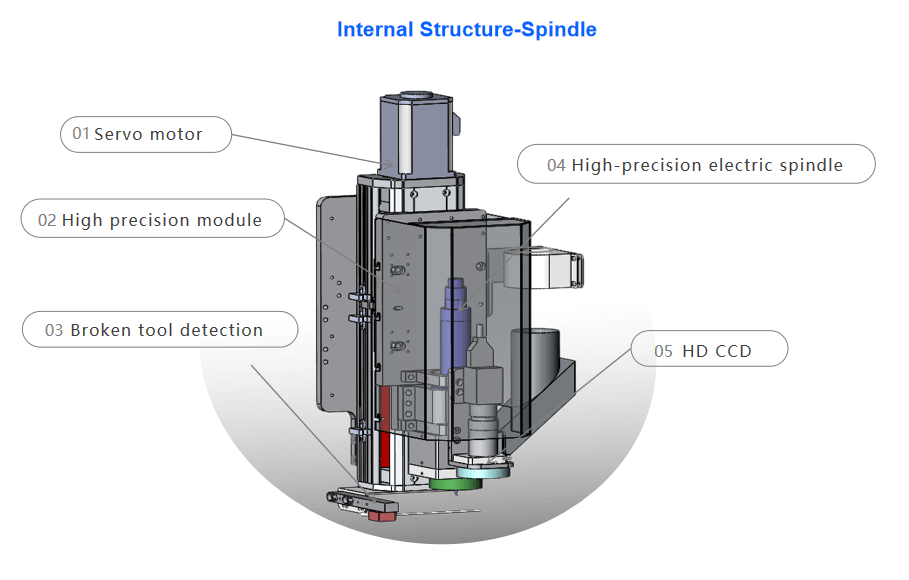

Spindle Rotating speed

|

MAX.60000RPM (adjustable)

|

MAX.60000RPM (adjustable)

|

|

Milling cutter replacement method

|

Manual replacement (Default)/ Automatic replacement (Optional)

|

Manual replacement (Default)/ Automatic replacement (Optional)

|

|

Cutting Speed

|

1~100mm/s (adjustable)

|

1~100mm/s (adjustable)

|

|

Operation Interface

|

Window10 system operation interface

|

Window10 system operation interface

|

|

Programming Method

|

Color CCD image visual teaching input

|

Color CCD image visual teaching input

|

|

Program Backup

|

one click recovery

|

one click recovery

|

|

XYZ Axis Drive Mode

|

AC servo motor

|

AC servo motor

|

|

Dust Vacuum Machine Power

|

Upwards vacuum 4P (3KW)

Upwards vacuum 6P (3KW)

Downwards vacuum 3HP (2.2KW)

Downwards vacuum 5HP (3.75KW)

|

Upwards vacuum 4P (3KW)

Upwards vacuum 6P (3KW)

Downwards vacuum 3HP (2.2KW)

Downwards vacuum 5HP (3.75KW)

|

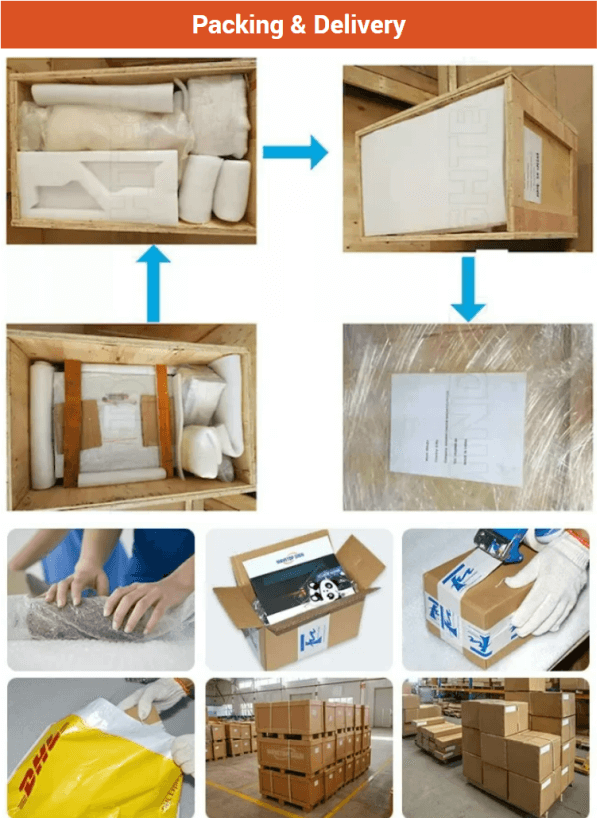

Product Description