Sustainable Screw Locking Automation | Eco-Friendly Assembly Solutions

In today's rapidly evolving industrial landscape, sustainability has become a critical focus for manufacturers worldwide. As industries strive to reduce their environmental footprint, automation technologies play an increasingly vital role in promoting eco-friendly practices. Screw locking automation, a key process in assembly operations, is no exception. By integrating sustainable methods into screw locking automation, companies can achieve significant environmental benefits while maintaining high efficiency and precision.

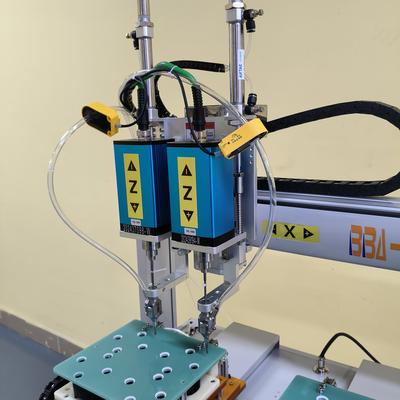

One of the primary ways screw locking automation contributes to sustainability is through energy efficiency. Modern automated screw locking systems are designed to optimize energy consumption. These systems utilize advanced motors and controllers that minimize power usage without compromising performance. For example, smart sensors and adaptive control technologies ensure that the equipment operates only when necessary, reducing idle time and wasted energy. This not only lowers operational costs but also reduces the overall carbon footprint of manufacturing processes.

Another important aspect is the reduction of material waste. Traditional manual screw locking processes often involve errors such as cross-threading, over-tightening, or under-tightening, leading to defective products and material waste. Automated systems, however, provide consistent and precise torque application, ensuring each screw is fastened correctly the first time. This accuracy minimizes rework and scrap, conserving raw materials and reducing waste. Additionally, many automated systems are equipped with real-time monitoring and feedback mechanisms, allowing for immediate detection and correction of any issues, further enhancing resource efficiency.

The longevity and durability of automated screw locking equipment also support sustainability goals. High-quality automation systems are built to last, with robust components that require minimal maintenance and replacement. This durability reduces the frequency of manufacturing new parts and disposing of old ones, contributing to a circular economy. Moreover, many manufacturers are now designing systems with modular components, making repairs and upgrades easier and extending the equipment's lifecycle.

Sustainable practices in screw locking automation also include the use of environmentally friendly materials and technologies. For example, some systems incorporate biodegradable lubricants and coatings or are free from harmful chemicals. Furthermore, the integration of IoT and data analytics enables predictive maintenance, which helps prevent unexpected breakdowns and reduces the need for emergency repairs, often associated with higher resource consumption and environmental impact.

In conclusion, adopting sustainable practices in screw locking automation is not only beneficial for the environment but also enhances operational efficiency and cost-effectiveness. By focusing on energy efficiency, waste reduction, equipment durability, and eco-friendly technologies, manufacturers can make significant strides toward greener production processes. As the demand for sustainable manufacturing continues to grow, investing in advanced screw locking automation will be key to achieving long-term environmental and economic goals.

| Product Name | Applicable Industries |

| Servo Screwdriver Robot | Smartphone Manufacturing |