Anti-Jamming Screw Feeder Design | Industrial Material Handling Solutions

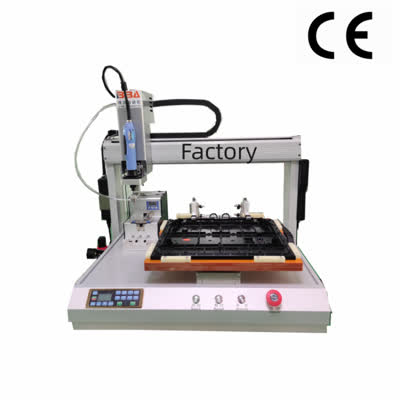

| Product Name | Applicable industries |

| Screw Fastening Unit | Consumer Electronics Assembly |

Anti-Jamming Design in Modern Screw Feeders

In the high-stakes environment of industrial automation, consistent and reliable material handling is paramount. Screw feeders, the workhorses of countless processes from food production to pharmaceuticals, are critical for precision dispensing and conveying. However, one of the most persistent challenges faced in their operation is jamming. A single jam can halt a production line, leading to costly downtime, material waste, and compromised product quality. Modern screw feeder design has therefore evolved significantly, prioritizing robust anti-jamming features that ensure seamless, uninterrupted operation.

Understanding the Root Causes of Jamming

Jamming typically occurs when the flow of material is obstructed, causing a buildup that prevents the screw from rotating. Common culprits include material bridging (where an arch forms over the screw), rat-holing (where material empties from the center leaving a stagnant outer ring), and the presence of overly cohesive, moist, or irregularly shaped particles. Traditional feeder designs often struggled with these issues, requiring frequent manual intervention.

Key Anti-Jamming Strategies in Contemporary Design

Today's engineers employ a multi-faceted approach to combat jamming, integrating mechanical, structural, and control-based solutions.

Advanced Hopper Geometry: The design of the hopper or supply bin is the first line of defense. Modern hoppers feature steep walls and specialized geometries, often with computer-modeled internal contours. These designs promote mass flow rather than funnel flow, ensuring the entire volume of material moves downward evenly toward the screw, effectively eliminating dead zones and preventing bridging.

Agitation and Vibration Systems: To break up clumps and encourage material movement, integrated agitators are a common solution. These can be rotating arms or pins located near the screw intake. Additionally, externally mounted vibrators are strategically used to impart high-frequency, low-amplitude vibrations to the hopper walls. This energy fluidizes the material, dislodging potential bridges and ensuring a consistent feed into the screw.

Screw and Tube Enhancements: The core components themselves have been re-engineered. Variable pitch screws, where the space between flights changes along the length, can help compress and break apart agglomerated material. For particularly challenging substances, tapered screws are effective. Specialized internal coatings on the screw and the surrounding tube reduce friction and material adhesion, a critical factor for sticky products.

Intelligent Control and Monitoring: Perhaps the most significant leap forward is the integration of smart control systems. High-torque drives are now standard, providing the necessary power to overcome minor obstructions without stalling. These are coupled with sophisticated sensors that continuously monitor torque and motor load. The controller can detect a sudden spike indicative of a jam and automatically initiate a response, such as briefly reversing the screw's direction to clear the blockage. This proactive approach prevents a full stoppage and maintains process integrity without operator input.

The Impact on Operational Efficiency

The implementation of these anti-jamming technologies delivers profound benefits. Production lines achieve higher levels of uptime and overall equipment effectiveness (OEE). There is a dramatic reduction in material waste caused by incomplete batches or cleaning cycles. Furthermore, automation is fully realized, as these systems can often run for extended periods without human intervention, enhancing safety and reducing labor costs.

In conclusion, anti-jamming design is not merely an add-on but a fundamental consideration in modern screw feeder engineering. By leveraging advanced geometries, mechanical agitation, component enhancements, and smart controls, manufacturers can ensure a continuous, reliable flow of materials. This commitment to innovation directly translates to more resilient, efficient, and profitable industrial operations, safeguarding productivity in the most demanding applications.