Step-by-Step Guide to Automated Screw Fastening | Industrial Servo Screwdriver Robot Applications in the LED Lighting Industry

| Product Name | Applicable industries |

| Servo Screwdriver Robot | LED Lighting Industry |

Step-by-Step Guide to Automating Screw Fastening in Industrial Applications

Automated screw fastening has revolutionized assembly lines by boosting precision, accelerating production cycles, and minimizing manual labor costs. This guide details a systematic approach to implementing this technology, ensuring optimal results for your operations.

Step 1: Requirement Analysis & Component Selection

Begin by documenting:

• Screw specifications: Head type (Phillips, Torx), dimensions, material tolerance

• Torque accuracy needs: Range (0.5–5 Nm typical) and precision (±3% standard)

• Cycle targets: Assembly speed (e.g., 5–20 sec/screw) based on line throughput

Step 2: System Configuration & Integration

Select components based on analysis:

• Feeding mechanisms: Vibratory bowls or tape feeders matched to screw dimensions

• Drive units: Electric or pneumatic screwdrivers with torque feedback sensors

• Positioning systems: Cartesian robots for linear paths or SCARA/articulated arms for complex geometries

Pro Tip: Use integrated vision systems to verify screw presence and detect cross-threading in real-time.

Step 3: Programming & Calibration

Define critical operational parameters:

1. Teach robot paths avoiding obstacles using waypoint mapping

2. Set torque profiles: Pre-torque (rapid spin) + Final-torque (precision tightening)

3. Program logic for error recovery (e.g., re-attempt sequences after misfeeds)

Step 4: Validation & Optimization

Execute phased testing:

- Dry runs without screws to validate collision-free paths

- Torque sampling (10–20 screws) using calibrated sensors

- 30-min continuous run at 80% speed to identify feeder jams

Adjust screw presentation angles and driver descent speeds based on test telemetry to achieve >99% success rate.

Step 5: Deployment & Maintenance Protocol

During rollout:

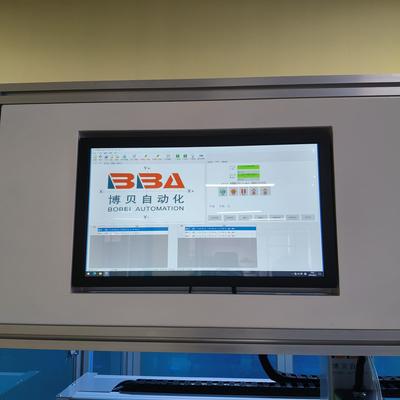

• Operational training: Teach technicians HMI controls and emergency stops

• Preventive schedule: Daily checks (feeder alignment), monthly driver calibration

• Data utilization: Monitor OEE dashboards to track downtime causes (e.g., fastener jams)

Benefits Realized Through Automation

Effective implementation delivers measurable outcomes:

Consistency: Eliminate under/over-torquing (defect reduction)

Efficiency: 3–8x faster than manual installation

ROI: Payback in 6–18 months via reduced labor/rework

Automating screw fastening transforms assembly quality while future-proofing production. By methodically following these steps, manufacturers can achieve seamless integration that scales with evolving operational demands.