Custom Fixtures for Multi-Axis Screwing | Precision Assembly Solutions

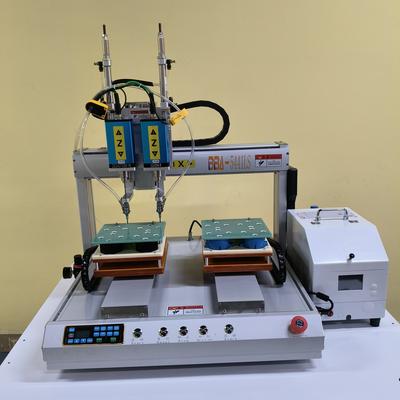

In today's high-speed manufacturing landscape, precision assembly processes define operational success. Multi-axis screwing applications present unique technical challenges where off-the-shelf solutions often fall short. Custom fixtures bridge this gap by enabling robotic systems to handle complex fastening tasks with unprecedented accuracy and repeatability. These purpose-built solutions transform multi-axis screwing operations from cumbersome procedures into seamless, high-yield processes.

Designing effective fixtures for multi-axis screwing begins with understanding spatial constraints and torque requirements. Engineers must account for angular access limitations, variable workpiece geometries, and thermal expansion factors during operation. Modular components prove invaluable, allowing fixtures to adapt to production changes without complete redesigns. Vibration dampening emerges as a critical consideration – high-frequency oscillations during fastening can compromise joint integrity if not addressed through strategic material selection and structural bracing.

Prototyping reveals hidden complexities that CAD models may overlook. Integrated force sensors in fixture prototypes provide real-time torque feedback, enabling refinement before full-scale deployment. This data-driven approach catches issues like fastener misalignment or material deflection that could cause costly production stoppages. Aerospace case studies demonstrate how fixtures with self-centering chucks reduced installation time for turbine blade screws by 40% while eliminating cross-threading defects.

Material durability directly impacts fixture longevity. Nickel-alloy reinforced mounts withstand repetitive stress where standard steel fatigues. Passive cooling channels embedded within fixture bodies prevent thermal distortion during extended production runs. The most advanced designs incorporate quick-release mechanisms that enable complete tooling changes in under 90 seconds – invaluable for high-mix manufacturing environments where components constantly evolve.

System calibration separates adequate fixtures from exceptional ones. Laser-aligned installation ensures sub-millimeter positional accuracy across all axes. Smart fixtures with embedded accelerometers now monitor vibration signatures during operation, automatically flagging deviations that indicate tool wear or workpiece inconsistencies. This predictive maintenance capability has reduced unexpected downtime by over 70% in automotive electronics assembly lines.

Success stories highlight the ROI potential. An appliance manufacturer eliminated 98% of stripped-screw defects after implementing guided Z-axis fixtures with automatic depth sensing. The investment yielded full payback within eight months through waste reduction alone. Similarly, a medical device producer achieved 192% throughput increase on their screwdriving cells using rotating fixture platforms that present optimal access angles without repositioning robotic arms.

Looking forward, fixtures are becoming intelligent subsystems rather than passive components. Microprocessor-controlled units now adjust clamping force dynamically based on material thickness variations detected via capacitance sensors. Such innovations prove particularly valuable for delicate assemblies like battery modules or micro-electronics where fastener tolerances approach microscopic precision. As workpieces become increasingly complex, purpose-engineered fixtures transition from luxury to operational necessity.

Custom fixture design transforms multi-axis screwing operations into strategic assets. Beyond resolving immediate production bottlenecks, these solutions future-proof assembly lines against product evolution and increasingly stringent quality requirements. The fusion of mechanical ingenuity and sensor technology creates adaptable production environments where precision fastening becomes a consistent, measurable advantage rather than a persistent challenge.

| Product Name | Applicable industries |

| Auto Screwdriver Machine | Automotive Electronics Assembly |