Precision Screw Fastening: The Key Solution for Enhancing PCB and SMT Assembly Quality

The Critical Role of Precision in Electronics Assembly

In PCB and SMT manufacturing, every micron matters. Screw fastening may seem like a simple step, but it’s a pivotal process that ensures reliability in electronic devices we depend on daily. From smartphones to medical equipment, improperly torqued screws can lead to component misalignment, cracked boards, or intermittent connections—failures that cost time, money, and reputation. With PCBs shrinking and component density rising, traditional manual methods fall short. Only precision-engineered screw driving systems guarantee the repeatability modern high-volume production demands.

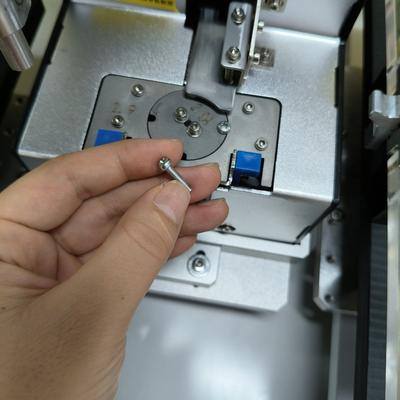

Overcoming Miniaturization Challenges

Modern electronics demand screw fastening solutions that navigate extreme constraints. Components crowd PCBs, leaving minimal clearance for screw placement. Fragile SMT parts risk damage from even slight misalignment or excessive force. Simultaneously, consistency is non-negotiable—each screw must meet exact torque and angle specifications across thousands of cycles. These challenges intensify in high-mix production, where rapid changeovers and material variations demand adaptable systems. Human operators, despite expertise, struggle to maintain micron-level accuracy at production-line speeds, necessitating intelligent automation.

Advanced Technology Driving Precision

Innovative screw fastening systems address these hurdles through integrated engineering. Servo-driven spindles deliver unparalleled control over torque (±1% accuracy) and angle, eliminating under/over-tightening. Collision detection halts operation instantly if resistance exceeds thresholds, protecting delicate boards from crush damage. Auto-feed mechanisms — using vibratory bowls or tape reels — present fasteners reliably to the driver, cutting cycles to under 1.5 seconds per screw. Vision-guided robotics precisely position drivers in cramped spaces as small as 2-3mm clearance zones while torque-angle graphing in real-time ensures every joint meets specification with encrypted data logs for full traceability.

Tangible Benefits for Electronics Manufacturers

Implementing precision screw driving translates to measurable gains. Assembly lines see 40-60% faster throughput with zero fatigue-related errors or rework. Defect rates plummet as controlled processes eliminate stripped threads and cracked substrates. Automated data capture provides digital proof of compliance, streamlining audits and reducing liability risks. Operators redeploy to higher-value tasks while alignment with Industry 4.0 frameworks enables predictive maintenance via system diagnostics. Scalability is seamless—modular designs accommodate everything from micro-screws in wearables to high-torque applications in automotive ECUs.

Securing the Future of Electronics Manufacturing

As PCBs grow denser and tolerances tighten, precision screw fastening remains a cornerstone of quality. Investing in advanced systems isn't optional—it's imperative for staying competitive. These technologies safeguard product lifetimes, ensure manufacturing agility, and build brand trust through flawless assembly. In the relentless pursuit of smaller, smarter devices, excellence in screw joining underpins innovation itself.

| Product Name | Applicable industries |

| CNC Screw Fastener | Security Equipment Manufacturing |