Assembly Automation Solutions for SMEs | High-Efficiency Production Line Upgrade

| Product Name | Applicable industries |

| Inline Screw Locking System | Electric Bicycle Assembly |

Assembly Automation for Startups and SMEs: Unlocking Efficiency Without Breaking the Bank

For startups and small-to-medium enterprises (SMEs), competing in today's manufacturing landscape can seem daunting. While large corporations leverage advanced automation, many emerging companies still rely on manual assembly – an approach that limits scalability and drains resources. The good news? Modern assembly automation is no longer exclusive to industry giants. With flexible, cost-effective solutions, smaller manufacturers can now harness the same transformative power.

The Hidden Costs of Manual Assembly

Manual processes create invisible barriers to growth. Hourly labor expenses accumulate rapidly, while human fatigue leads to inconsistent output and costly errors. Training and turnover further strain budgets, and scalability becomes nearly impossible during demand surges. For resource-constrained businesses, these challenges can stall innovation and erode profit margins.

Automation Designed for Growing Businesses

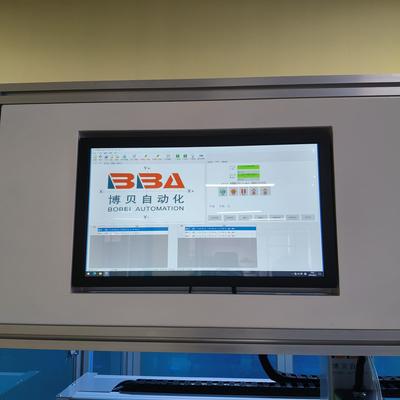

Contemporary automation solutions shatter old paradigms. Modular systems allow you to start small: automate a single critical station like screwdriving or precision placement, then expand as production scales. User-friendly programming interfaces require minimal technical expertise, and rapid reconfiguration capabilities accommodate product changes without costly downtime. Crucially, these systems offer compelling ROI – often paying for themselves within 18 months through labor savings and defect reduction.

Transformative Benefits for SMEs

- Precision Perfected: Achieve micrometer-level accuracy consistently, eliminating human variability.

- 24/7 Productivity: Systems operate tirelessly through breaks and shifts, boosting output by up to 300%.

- Quality Assurance: Integrated sensors detect errors in real-time, preventing defective products from advancing.

- Resource Optimization: Redirect skilled workers from repetitive tasks to value-adding roles like R&D and process improvement.

Getting Started Simplified

Implementation needn't be overwhelming. Identify bottlenecks through process mapping, then prioritize automating the highest-impact area. Many providers offer scalable solutions that grow alongside your operation, with minimal upfront investment. Look for systems featuring plug-and-play components and intuitive software that reduce integration complexity.

Future-Proof Your Operation

In an era where agility defines competitiveness, automation is the catalyst SMEs need. It transforms production floors into strategic assets – driving down costs while elevating quality and throughput. Whether assembling electronics, medical devices, or consumer goods, automated systems provide the foundation for sustainable scaling and market differentiation.

The leap into automation isn't a luxury reserved for Fortune 500 companies. With tailored, accessible technologies, startups and SMEs can now unlock unprecedented efficiency and position themselves not just to compete, but to lead in their industries.