Servo vs Pneumatic Screw Drivers Performance Comparison | Industrial Assembly Tech

| Product Name | Applicable industries |

| Inline Screw Locking System | Industrial Control Panel Assembly |

Measuring Performance: Servo vs Pneumatic Screw Drivers

In industrial assembly operations, screw driving is a critical process where precision, speed, and reliability directly impact productivity and product quality. Two dominant technologies—servo electric screwdrivers and pneumatic screwdrivers—serve this function, each with distinct performance characteristics. Understanding their operational differences is essential for optimizing assembly processes and minimizing total operating costs.

Torque Accuracy and Process Control

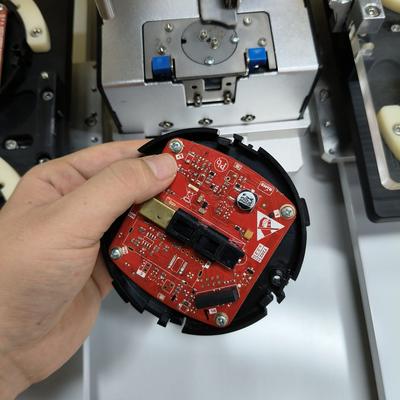

Servo electric screwdrivers utilize brushless DC motors with integrated encoders, providing closed-loop feedback that achieves torque accuracy within ±2%. This enables precise control over angular rotation, speed profiles, and peak torque. For applications requiring sequential multi-stage tightening (e.g., soft-start followed by final torque), servo systems automatically adjust parameters between steps without mechanical recalibration.

Pneumatic screwdrivers rely on compressed air driving a turbine or piston actuator. Torque control is typically open-loop, dependent on airflow pressure and mechanical clutches, resulting in accuracy deviations of ±10-15%. Environmental variables like air pressure fluctuations or temperature changes further impact consistency, making precise torque profiling challenging without additional sensors.

Speed, Energy Efficiency, and Noise

Pneumatic models excel at high-speed, repetitive tasks, often completing single fastening cycles faster than servo equivalents due to unrestricted air-driven acceleration. However, their overall efficiency is constrained by energy losses inherent to compressed air systems: compressors typically convert 70-80% of electrical input into heat, while air leaks and line pressure drops cause additional waste. Sustained operation also generates noise levels exceeding 85 dB, necessitating hearing protection.

Although peak rotational speed may be lower, servo electric drivers narrow the speed gap through instantaneous start/stop response times (<50ms) and regenerative braking. They consume energy only during active tightening cycles, reducing typical power consumption by 40-60% compared to pneumatic systems. Servo operation remains near-silent (<65 dB), improving working conditions and eliminating fluid mist contamination from exhaust air.

Traceability and Maintenance Requirements

Servo drivers incorporate embedded processors enabling real-time data capture for every fastening cycle. Torque-angle curves, cycle times, error codes, and operator IDs are automatically logged locally or transmitted via Ethernet/IP to MES/SCADA systems. This supports quality audits, predictive maintenance, and automated process validation—critical for industries demanding full traceability.

Most pneumatic screwdrivers lack native data collection. Pneumatic components like valves, filters, and seals require regular maintenance to prevent air leaks and pressure decay. Filters must be drained weekly, lubricators refilled monthly, and seals/rotors replaced annually. Servo systems eliminate lubricant-related maintenance, with brushless motors lasting over 10,000 operating hours. Only intermittent gearbox lubrication may be necessary.

Economic Considerations

While pneumatic screwdrivers offer lower upfront costs, servo drivers deliver significant operational savings:

- Energy: Servo systems reduce electricity costs by ≤75% by eliminating compressed air generation losses.

- Scrap Reduction: Enhanced torque precision reduces assembly defects and rework expenses by up to 30%.

- Downtime: Lacking air-dependent components cuts maintenance-induced stoppages by 15-25%.

Applications involving sensitive electronics, medical devices, or complex multi-stage sequences typically justify selecting servo electric drivers despite higher initial capital outlay. Functions like automated screw feeding with electronic height sensing further consolidate processes into a single servo-controlled workflow.

The Operational Landscape Ahead

Pneumatic screwdrivers remain viable for single-speed fastening in cost-focused environments with minimal torque accuracy requirements. However, metrics now overwhelmingly favor servo electric technology for modern manufacturing: its electrical efficiency complements sustainability initiatives, precision tightening reduces failure risks, and Industry 4.0 integration capabilities future-proof assembly lines.

For facilities prioritizing data-driven quality control, lower total lifecycle costs, or ergonomic enhancements, servo-driven systems deliver measurable advantages. As servo motor costs continue to decline while performance rises, the long-term trajectory points toward wider electric adoption across industrial automation landscapes.