Screw Feeding Systems Evolution: Automation & Industry 4.0 Innovations

| Product Name | Applicable industries |

| Screw Locking Robot | PCB and Circuit Board Assembly |

The evolution of screw feeding systems represents a cornerstone of innovation in industrial automation. From rudimentary manual processes to today’s advanced robotic and AI-driven solutions, these systems have transformed assembly workflows, enabling unprecedented precision, speed, and reliability. This progression not only reflects technological advancement but also underscores the growing demands of modern manufacturing.

Early Stages: Manual Labor and Mechanical Beginnings

In the early 20th century, screw fastening relied exclusively on human labor. Workers manually aligned screws, tightened them using handheld tools, and managed inventory without standardized processes. While functional for low-volume production, this approach proved error-prone and inefficient as industries scaled. The introduction of mechanical screw feeders in the 1950s marked the first shift toward automation, using gravity-driven tracks and vibratory bowls to sort and orient screws. These systems minimized human intervention, paving the way for higher throughput.

The Rise of Semi-Automated Systems

By the 1980s, semi-automated systems integrated pneumatic and electromechanical components to enhance precision. Programmable logic controllers (PLCs) allowed operators to adjust feed rates and torque settings, while sensors detected jams and orientation errors. This era reduced downtime and improved adaptability but remained constrained by limited compatibility with diverse screw types and sizes.

Intelligent Automation in the Digital Age

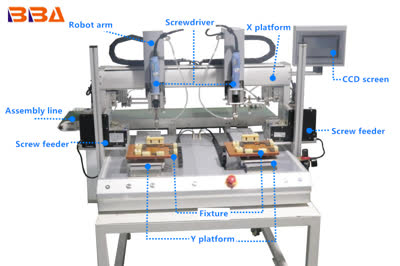

Today’s screw feeding systems leverage IoT connectivity and machine learning for predictive maintenance and adaptive control. Robotic arms equipped with vision systems autonomously identify screw positions, adjust torque dynamically, and integrate seamlessly with assembly lines. Machine learning algorithms analyze historical data to optimize feed paths, minimizing cycle times. These innovations align with Industry 4.0 principles, enabling scalability across automotive, electronics, and aerospace sectors.

Key Drivers of Advancement

Three factors propel screw feeding system evolution: demand for lean manufacturing, stricter quality standards, and customization needs. High-speed production lines require zero-defect outputs, achieved through real-time monitoring and automated correction. Meanwhile, modular designs now accommodate diverse materials — from micro-screws in electronics to hardened variants in heavy machinery — without significant reconfiguration.

Future Prospects

The next frontier involves AI-driven self-optimization, where systems autonomously adapt to new screw geometries and torque specifications. Sustainable practices, such as using recyclable materials in feeder components and energy-efficient motors, will also gain prominence. As collaborative robots (cobots) become mainstream, decentralized feeder systems embedded within modular workstations may redefine flexible manufacturing paradigms.

Conclusion: The trajectory of screw feeding systems mirrors the relentless pursuit of efficiency and precision in modern industry. By embracing digitalization and intelligent automation, these systems will continue to play a pivotal role in shaping the factories of tomorrow.